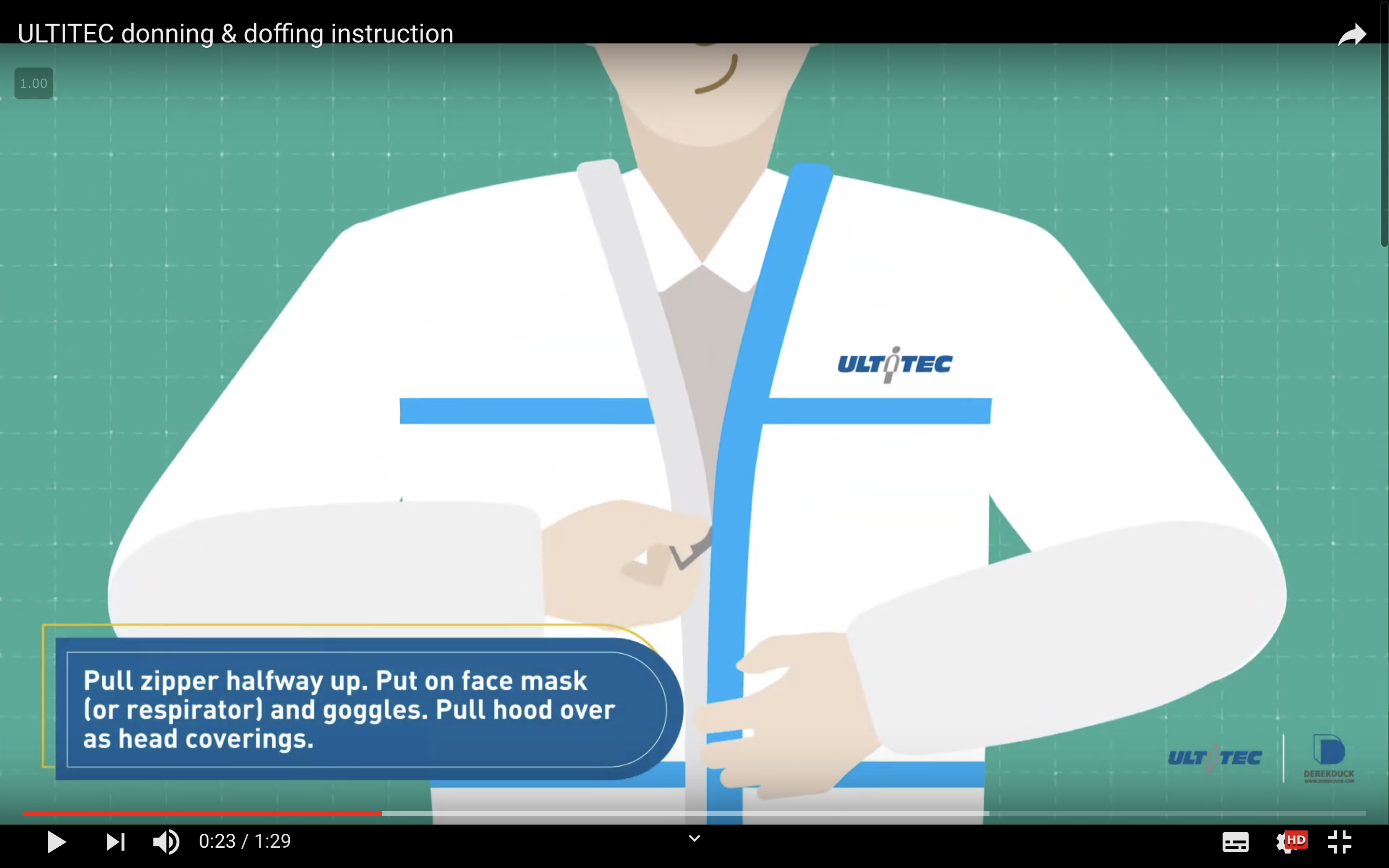

Imagine that you have finished a whole day long work, feeling exhausted and couldn’t wait to go home earlier and catch up for dinner with your family. In the meantime, you were chatting with colleagues while doffing your protective clothing. Suddenly, you felt a chemical burn on your body parts……

DD2019-10-31