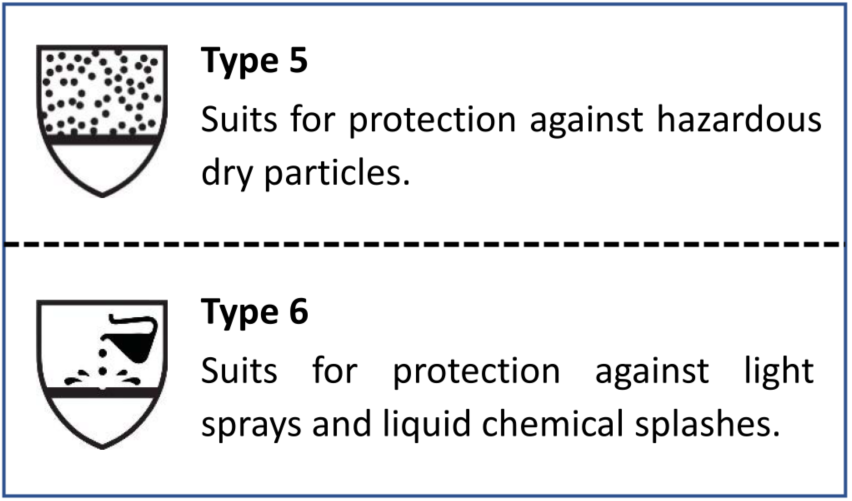

If you missed the A+A trade fair last week, don't worry! Here's a recap of some of the highlights:Highlight 1: Protective Clothing Series Our coveralls are designed to protect you from a wide range of hazards in different environments. From Type 6 to Type 3, we have the perfect solution…

Hannah2023-10-30