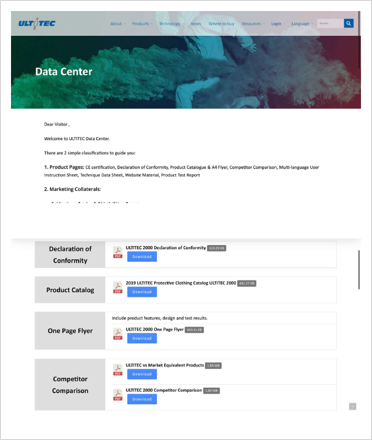

ULTITEC participated in the 2020 Healthcare+ EXPO, which was the largest medical professional exhibition after the outbreaks of the COVID-19 epidemic in Taiwan. There were 500 exhibitors, institutions and enterprises in medical, electronic information, technology, biotechnology, pharmaceuticals, and medical materials industries. ULTITEC exhibited in the category of “Infectious Disease Prevention…

Hannah2020-12-08