ULTITEC 1000FR

Particles, Light Chemical Spray & Flame-Retardant Protective Clothing

Protect wearers and their reusable flame-resistant suit from limited flame spread and chemicals.

Features

- Meet EN ISO 14116 Index 1, offer limited flame spread protection for your high-price flame resistant garment.

- Provide protection for chemical hazards.

Notes:

According to EN ISO 14116 Index 1, the limited flame spread coverall must never be in direct contact with skin. The ULTITEC 1000FR must be always worn on top of index 2 or 3 thermal protective garments and hoods.

- TYPE 5 EN ISO 13982-1 Dry Particle Suits-Suits for protection against hazardous dusts and any dry particles.

- TYPE 6 EN 13034 reduced spray -suits which offer limited protection against a light spray of liquid chemicals.

- EN ISO 14116 Limited flame spread materials, material assemblies and clothing.

- EN 1073-2 Protective clothing against particulate radioactive contamination.

- EN 1149-5 Electrostatic dissipative protective clothing with a surface resistance of maximum 2.5×10 exp 9 ohm.

Applications

Gas & Oil, Metal Welding, Petrochemical, Railway, Utilities

Color

- Blue

- White

Product Technology

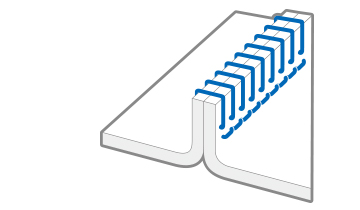

Seam Construction

4-thread Overlocked Seam

- 7-9 stitches per inch

- Thread fiber is 150D

- Bite depth 4 mm

Fabric Construction

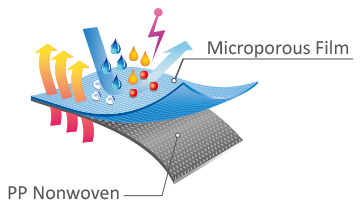

Front Fabric

Microporous Film laminate PPSB

- MVTR is above 5000 gsm / 24hr (ASTM E96 BW)

- Hydro-head is above 2000 mm-H2O(ISO 811)

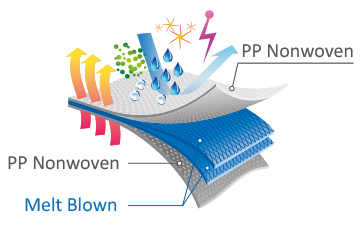

Multilayer SMMS fabric

Performance Chart

- Scroll the form to see more.

| FABRIC PHYSICAL PROPERTIES | TEST METHOD | CLASS | |

|---|---|---|---|

| Abrasion Resistance | EN 530 | 2 | |

| Flex Cracking Resistance | EN ISO 7854/B | 6 | |

| Trapezoidal Tear Resistance | EN ISO 9073-4 | 2 | |

| Tensile Strength | EN ISO 13934-1 | 1 | |

| Puncture Resistance | EN 863 | 1 | |

| Seam Strength | EN ISO 13935-2 | 3 | |

| Antistaticity | EN 1149-5 | Pass | |

| pH Value | EN ISO 3071 | Pass | |

| Colour Fastness to Perspiration | EN ISO 105-E04 | Pass | |

| Resistance to Ignition | EN 13274-4 | Pass | |

| AZO colourants | EN 14362-1 | Pass | |

| Limited Flame Spread* | EN ISO 14116 | INDEX 1 | |

| Moisture Vapor Transmission Rate | ASTM E96 B | 11,975 g/m²*24hr | |

| Water Vapour Resistance [Ret] | EN ISO 11092 | 3.5m²*Pa/W |

*Only fabric reach EN ISO 14116 requirement

| CHEMICAL PROPERTIES | TEST METHOD | PENETRATION | REPELLENCY |

|---|---|---|---|

| Sulfuric acid 30% | EN ISO 6530 | Class 3 | Class 3 |

| Sodium Hydroxide 10% | EN ISO 6530 | Class 3 | Class 3 |

| WHOLE SUIT TEST PERFORMANCE | RESULT | |

|---|---|---|

| Type 5 | Inward Leakage Test | Pass |

| Type 6 | Reduced Spray Test | Pass |

| EN 1073-2 | Against Radioactive Contamination | Class 1 |

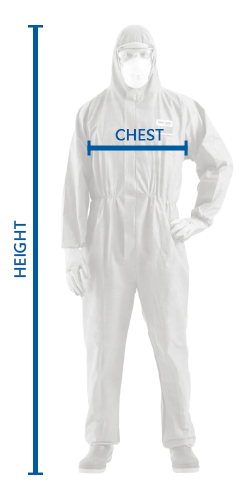

Coverall Size Chart

| SIZE | CHEST(CMS) | HEIGHT(CMS) |

|---|---|---|

| S | 84-92 | 162-170 |

| M | 92-100 | 170-176 |

| L | 100-108 | 176-182 |

| XL | 108-116 | 182-188 |

| 2XL | 116-124 | 188-194 |

| 3XL | 124-132 | 194-200 |

| 4XL | 132-140 | 200-206 |