ULTITEC 2000

Premium Oil, Liquid Splash & Infective Agents Resistant Protective Clothing

Designed to protect wearers against heavy liquid splash and biological hazards. The most popular and widely applied choice in various industries.

Features

An Effective Barrier Against Blood, Body Fluids and Infective Agents

The fabric performance exceeds both WHO protective clothing specification Option 1 & 2 for Ebola Virus Disease Infection Control. [Note*]

Proven protection against pesticides

Meets DIN 32781 requirement on pesticide penetration and comfort for agriculture application.

Breathable to Work Efficiently

Designed for comfort use. Allow wearers to work efficiently while releasing their body heat to prevent heat exhaustion.

Low linting

Reduces the risk of fiber contamination to the work environment.

Breathable to Work Efficiently

Designed for comfort use. Allow wearers to work efficiently while releasing their body heat to prevent heat exhaustion.

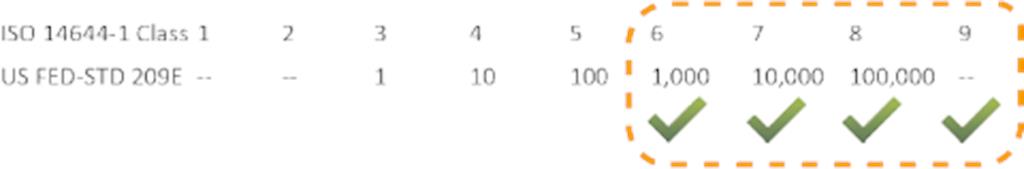

Targeted for ISO class 6 and above cleanroom with controlled environment.

Note*: The WHO recommended specification for coveralls against filovirus disease issued in Oct, 2014 stated that healthcare workers should choose appropriate protective apparel, which meets the following two requirements:

option 1, tested for resistance to blood and body fluid penetration: meets or exceeds ISO 16603 class 3 exposure pressure.

option 2, tested for resistance to blood-borne pathogen penetration; meets or exceeds ISO 16604 class 2 exposure pressure.

Note**: ULTITEC 2000 coverall is suitable for both ISO 14644-1 and US FED-STD 209E cleanroom standard. Test result shown in the following table:

- TYPE 5 EN ISO 13982-1 Dry Particle Suits-Suits for protection against hazardous dusts and any dry particles.

- TYPE 6 EN 13034 reduced spray -suits which offer limited protection against a light spray of liquid chemicals.

- EN 14126 Protective clothing can resist against biological hazards and infective agents.

- EN 1073-2 Protective clothing against particulate radioactive contamination.

- EN 1149-5 Electrostatic dissipative protective clothing with a surface resistance of maximum 2.5×10 exp 9 ohm.

Applications

Agriculture, Automotive, Biological Hazards, Disaster Management, Disease Control, Electronic Industries, Pharmaceutical, Petrochemical, Painting

Color

- White

Product Technology

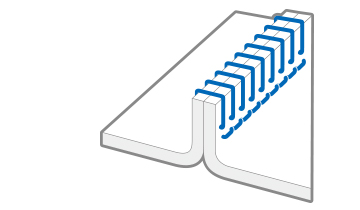

Seam Construction

4-thread Overlocked Seam

- 7-9 stitches per inch

- Thread fiber is 150D

- Bite depth 4 mm

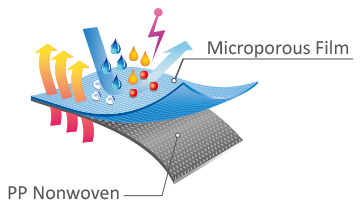

Fabric Construction

Microporous Film Laminate PPSB

- Ret Value: 21.0 m²*Pa/W

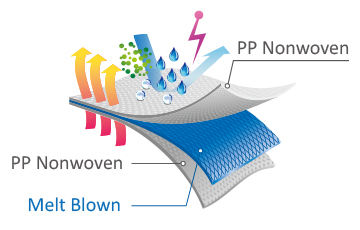

Back Fabric

Multilayer SMS fabric

Performance Chart

- Scroll the form to see more.

| PHYSICAL PROPERTIES | TEST METHOD | CLASS | |

|---|---|---|---|

| Abrasion Resistance | EN ISO 12947-2 | 2 | |

| Flex Cracking Resistance | EN ISO 7854-B | 6 | |

| Trapezoidal Tear Resistance | EN ISO 9073-4 | 2 | |

| Tensile Strength | EN ISO 13934-1 | 1 | |

| Puncture Resistance | EN 863 | 2 | |

| Seam Strength | EN ISO 13935-2 | 3 | |

| Antistaticity | EN 1149-5 | Pass | |

| pH Value | EN ISO 3071 | Pass | |

| Resistance to Ignition | EN 13274-4 | Pass | |

| Moisture Vapor Transmission Rate (MVTR) | ASTM E96B | 7,123 g/m²*24hr | |

| Water Vapour Resistance (Ret) | EN ISO 11092 | 21.0 m²*Pa/W |

| CHEMICAL PROPERTIES | TEST METHOD | PENETRATION | REPELLENCY |

|---|---|---|---|

| Sulfuric acid 30% | EN ISO 6530 | Class 3 | Class 3 |

| Sodium Hydroxide 10% | EN ISO 6530 | Class 3 | Class 3 |

| o-Xylene | EN ISO 6530 | Class 3 | Class 3 |

| Butan-1-ol | EN ISO 6530 | Class 3 | Class 3 |

| AGAINST INFECTIVE AGENTS with EN 14126 | TEST METHOD | CLASS | |

|---|---|---|---|

| Resistance to penetration by blood / fluids | ISO 16603 | 6 | |

| Resistance to penetration by blood-borne pathogens | ISO 16604 | 6 | |

| Resistance to wet microbial penetration | ISO 22610 | 6 | |

| Resistance to liquid aerosol penetration | ISO/DIS 22611 | 3 | |

| Resistance to dry microbial penetration | ISO 22612 | 3 |

| WHOLE SUIT TEST PERFORMANCE | RESULT | |

|---|---|---|

| Type 5 | Inward Leakage Test | Pass |

| Type 6 | Reduced Level Spray Test | Pass |

| EN 1073-2 | Against Radioactive Contamination | Class 1 |

Related Articles

-

What Protective Clothing Is Appropriate for Novel Coronavirus (2019-nCoV) Disease Control ?

-

PPE Preparation for Animal Disease Control and Management

-

How Well Do You Understand EN 14126:2003? Protection Against Biological Agents in Workplace

-

Understanding EN 14126:2003 for Battle Against COVID-19

-

How Well Do You Understand Asbestos Protection?

-

ULTITEC 2000 & ULTITEC 1000L protective clothing applied for Turkey gas plant asbestos removal operation

-

Outbreaks of African Swine Fever could Spill into Southeast Asia Protective Clothing Needed for Disease Control

-

Challenge of Global Preparedness for H1N1 Influenza Pandemic

-

Asia Prepares for Crop Battle with Fall Armyworm (FAW)

-

Ebola Lessons for Global Health and PPE Preparedness during Outbreak

Related Videos

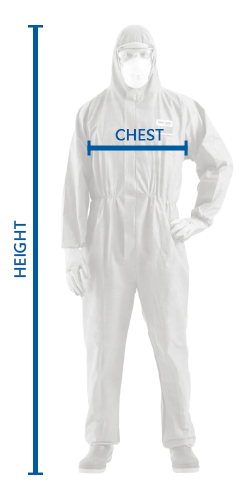

Coverall Size Chart

| SIZE | CHEST(CMS) | HEIGHT(CMS) |

|---|---|---|

| S | 84-92 | 162-170 |

| M | 92-100 | 170-176 |

| L | 100-108 | 176-182 |

| XL | 108-116 | 182-188 |

| 2XL | 116-124 | 188-194 |

| 3XL | 124-132 | 194-200 |

| 4XL | 132-140 | 200-206 |