According to European Commission, Regulation (EU) 2016/425 covers the design, manufacture and marketing of PPE. It defines legal obligations to ensure PPE on the EU internal market provides the highest level of protection against risks. The CE mark affixed to PPE will provide evidence of compliance which product applicable to EU legislation. It indicates risk categories of which PPE is intended to protect users, such as protective clothing complies with Category III is appropriate to prevent death or irreversible health damages.

Standard Definition of Protective Clothing

In order to facilitate selection of appropriate protective clothing, the European Union has listed different standards of protection and its pictogram.

Chemical Protective Clothing – Category III

| Standard | Pictogram | Definition |

| TYPE 1 |  |

Gas-tight protective clothing |

| TYPE 2 |  |

Non-gas-tight protective clothing |

| TYPE 3 |  |

Protection against pressurized liquid jet |

| TYPE 4 |  |

Protection against saturated liquid splash |

| TYPE 5 |  |

protection against harmful particulates |

| TYPE 6 |  |

Protection against liquid spray |

| Standards | Pictogram | Definition |

| EN 1073-2 |  |

Protection against radioactive contamination |

| EN 1149-5 |  |

Electrostatic dissipative protective clothing |

| EN 14126 |  |

Protection against biological hazards |

| DIN 32781 |  |

Protection against pesticides |

| EN ISO 14116 |  |

Protection against limited flame spread |

Test Method for Standard Categorization

For protective clothing to pass standard tests, it must meet or exceed minimum requirements of materials’ physical and chemical properties. Once test results are confirmed, it is qualified to carry standard pictogram and need to be correctly identified or labeled on marketing materials.

Type 1 EN 943-1 Gas-tight suits / Type 2 EN 943-1 Non-gas-tight suits

Performance requirements for ventilated and non-ventilated ‘Gas-tight’ (Type 1) and ‘Non-gas-tight’ (Type 2) chemical protection suits.

- Type 1a:Self-contained breathing apparatus worn on the inside.

- Type 1b:Self-contained breathing apparatus worn on the outside.

- Type 1c:Air supply via a compressed-air hose system.

- Type 2:Ventilated and positive pressure by air supply via a compressed-air hose system.

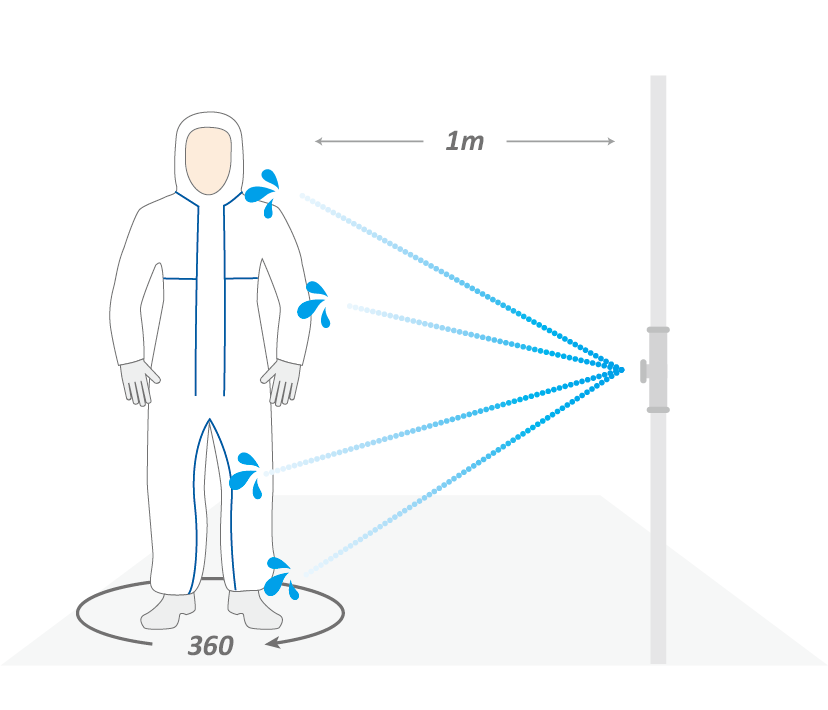

TYPE 3 EN 14605 Liquid Jet Suits

Determination of resistance to penetration by a jet of liquid

|

|

|

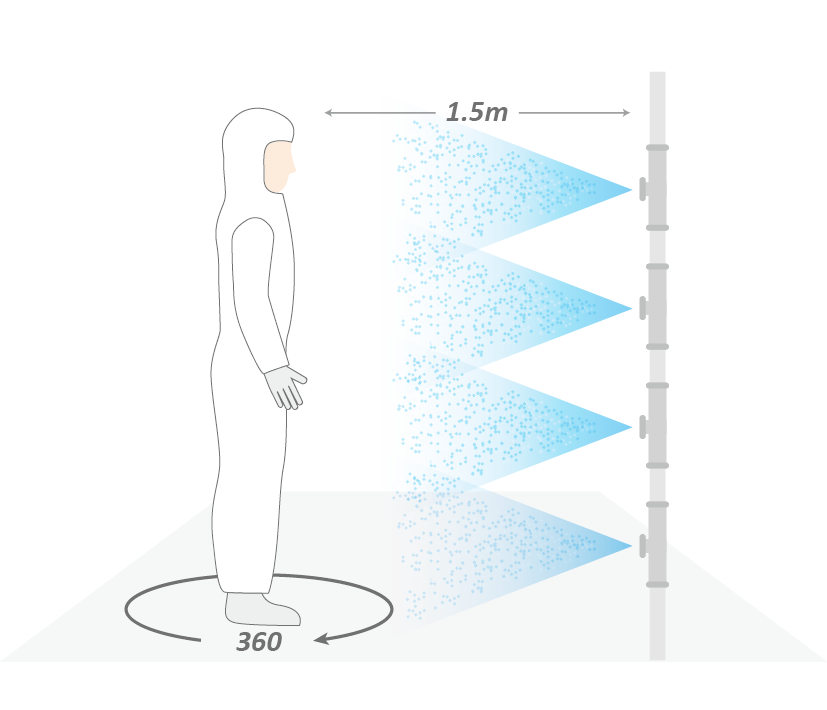

TYPE 4 EN 14605 Liquid Jet Suits

Determination of resistance to penetration by liquid spray

|

|

|

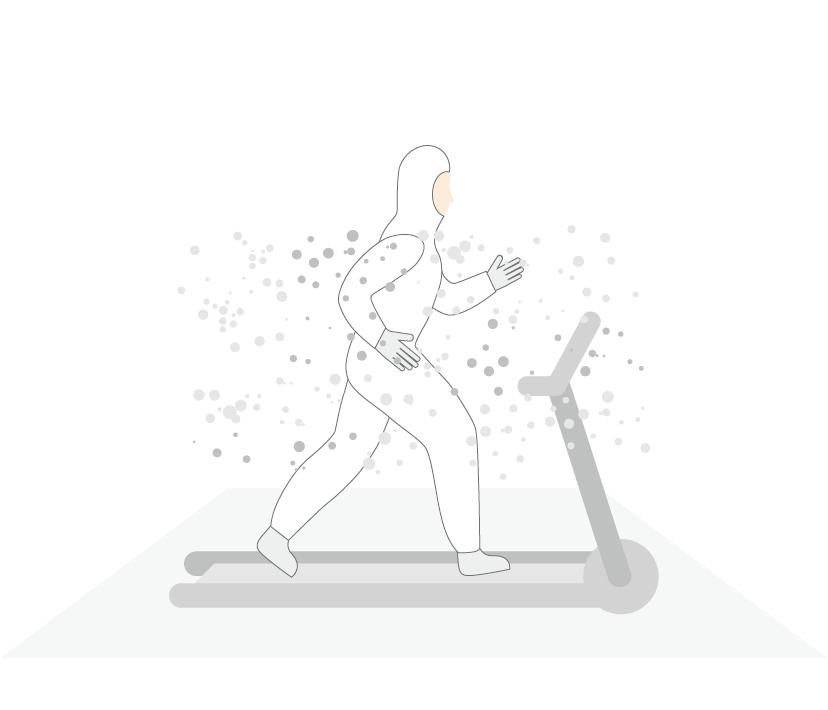

TYPE 5 EN ISO 13982-1 Particulate Tight Suits

Determination of inward leakage of aerosols & solid particles

|

|

|

TYPE 6 EN 13034 Reduced Spray Suits

Determination of resistance to penetration by reduced liquid spray

|

|

|

EN 1073-2 Against Radioactive Contamination

Determination of inward leakage of aerosols & solid particles

|

|

|

EN 1149-5 Antistatic

- The standard specifies a set of requirements and test methods to measure the fabric protection against static electricity or charge decay

- Electrostatic resistance is required when the wearer is exposed to environments where sparks could cause explosions or ignition

- Coveralls according to this standard do not offer protection from main voltages

EN 14126 Against Biological Hazards

- The standard specifies a set of requirements and test methods to measure the fabric protection against infective agents

- ISO 16603, ISO 16604, ISO/DIS 22611 determines penetration by blood, body fluids, blood borne and biologically contaminated aerosol

- ISO 22612, ISO 22610 determines the resistance of dry and wet microbial penetration

DIN 32781 Against Pesticides

- The test standard covers requirements in chemical penetration, fabric strength and ergonomics.

- The certification includes EN 14786, which simulates liquid spray of drugs

- Five different pesticides including U46-D-Fluid (BASF), Pirimor Granulat (Syngenta), Amistar(Syngenta), Betanal Expert(Bayer), Folicur(Bayer) are tested to ensure protection against pesticides

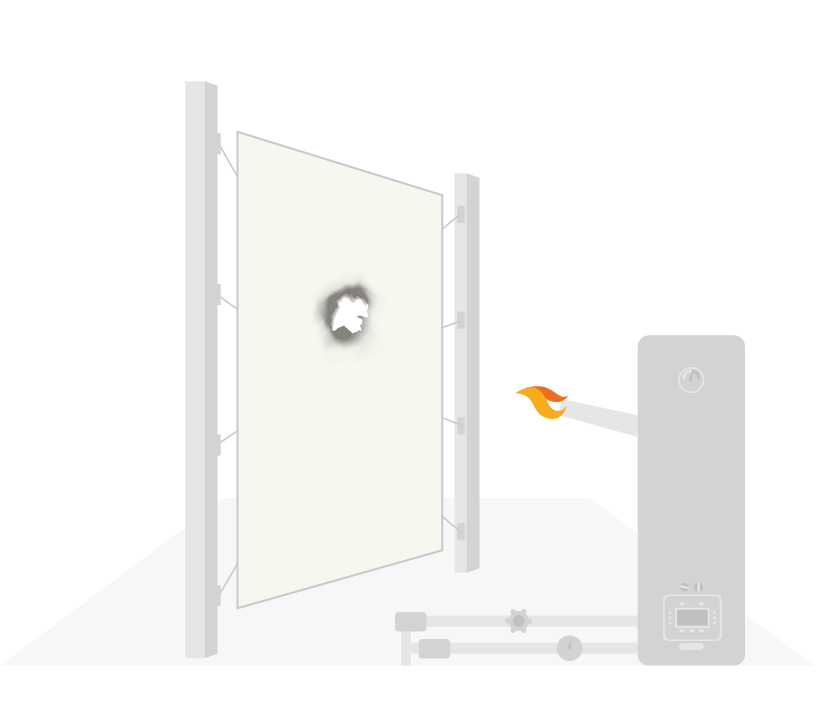

EN ISO 14116 Flame Retardant Test

To check whether the fabric/materials burn while contacting heat source. Whether the fabric stops flame spreading if burned

|

|

Requirements for limited flame spread Index 1

|

Other Key Consideration Factors

The standard pictogram means the protective clothing meets certain minimum requirements with controlled environment and variables. However, in the reality, wearers dealing with hazards may face uncertainties in workplace. Therefore, it is essential to take below factors into consideration:

- Environment Risk – Identify potential hazards assessments including states of matter, chemical temperature and estimated exposure time.

- Design of Protective Clothing – Smart fitting ensures protective clothing provides wearers with comfort and appropriate protection.

- Correct Usage – Correct donning and doffing process secure wearers from exposure of hazards and avoid contamination.

In conclusion, understanding of standard is relatively important to assist selection of appropriate PPE to meet workplace safety requirements. The little yet important pictogram label on ULTITEC indicates an assured level of safety and compliance with European standards. Do remember that no garment can provide absolute protection against all chemical exposures in all conditions, but higher protection level protective clothing is relatively more appropriate in managing uncertainty in the workplace.

COVID-19 Protection Articles: