In recent years, there are two largest epidemics, Dengue Fever and the COVID-19, which occurred across Latin America. The Dengue fever epidemic has started in late 2018, whereas the COVID-19 has begun in early 2020 and both are still lasting. According to the Pan American Health Organization (PAHO), in 2019, Dengue caused over 3 million infections in the Americas with more than 1,500 deaths in Latin America and the Caribbean.

Dengue Fever is a mosquito-borne disease and transmitted to humans by female mosquitoes from the species Aedes aegypti. People who are infected by the Dengue virus will have severe joint pain so that Dengue fever is also colloquially called breakbone fever. To control and prevent Dengue, the most effective solution is reducing the population of mosquitoes and keeping the environment sanitized for eliminating the breeding sites.

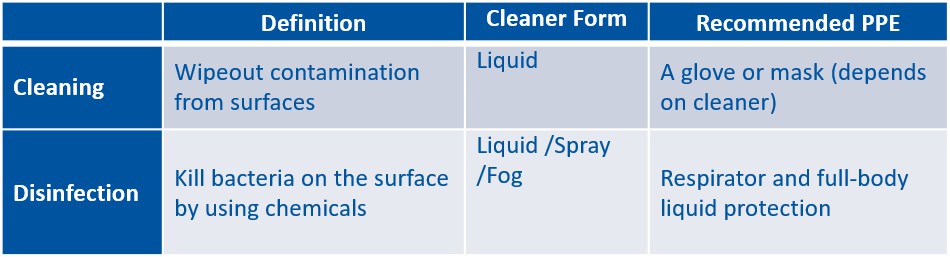

The Novel Coronavirus which caused COVID-19 is transmitted between people directly or indirectly through contaminated objects or surfaces by infected physical contact and respiratory droplets. For minimizing the risks of being infected by indirect contact with humans, cleaning and disinfecting are practical ways.

Figure 1: Cleaning and disinfection to ensure flight cabin safety. (Photo credit to: Jakarta Globe)

As the outbreak of COVID-19 in 2020 has pulled global attention and resources away, even some actions to reduce COVID-19 can contribute to a rise in dengue cases. For instance, the mandated lockdowns have resulted in most of the cases of transmission by mosquitoes occurred since people spend more time staying at home, where is an ideal environment for dengue’s transmission. However, there is one similar and effective action that can be taken for preventing both epidemics i.e. cleaning and disinfecting of the environment.

Some people would use clean water and soap for cleaning; however, other people tend to utilize the chemical detergent to sterilize at the same time. With a wide range of cleaner and various chemical formulation, it is strongly recommended that the users shall always wear gloves or masks while cleaning.

Furthermore, protective clothing is suggested for the frontline operators to wear while doing the cleaning and disinfection tasks in the potentially contaminated work environment since their skin could be at the risks of exposure to the chemical fine fog or contaminated objects during the cleaning process. Therefore, the frontline operators shall be equipped with gloves, masks, and protective clothing for avoiding contact with risky objects while cleaning and disinfecting at the workplace.

Table 1: Difference between Cleaning and Disinfection

Here is the guideline for selecting an appropriate PPE for cleaning and disinfection.

1. Chemical liquid-resistant material

Having a chemical and liquid resistant material for PPE plays an important role for the frontline operators since most cleaning agents come in liquid form and the precautions to prevent skin exposure from chemical substances can be taken in this way. The related PPE standards can be referred to the EN 13034 Type 6 and DIN 32781 certifications which are relevant standards under the liquid process.

EN 13034, Type 6 Reduced Spray Suits

The suits that protect against light spray and splashes of liquid from chemicals which are omnidirectional spray or the build-up of fluid on the suit as well as the fine mist of droplets in the atmosphere.

DIN 32781, Against pesticides

The test standard covers requirements in chemical penetration, fabric strength and ergonomics. It includes EN 14786, which simulates liquid spray of drugs. Besides, there are five different pesticides, including U46-D-Fluid (BASF), Pirimor Granulat (Syngenta), Amistar (Syngenta), Betanal Expert (Bayer) and Folicur (Bayer) are tested to ensure protection against pesticides.

If the cleaner contains highly toxic chemicals, or the volume is heavier than normal use, you may consider a more strict standard for the coverall.

EN 14605 Type 4 Spray Tight Suits

Suits which can protect against saturation of liquid chemical, where the volume of the liquid builds up on the suit forming pools, resulting in rivulets. It requires a barrier fabric and sealed seam

2. Durable and safe design

The PPE used in cleaning and disinfection should be durable because many kinds of protective gear will be equipped at the same time. Check cleaner’s labels and Safety Data Sheets (if available) to know the potential hazards. Durable material may resist breaking or crack while the operator is executing the tasks and requiring a bigger movement such as squat down and so on. To ensure the safety level, it is better to pay more attention to the Data Sheet for understanding the basic physical properties of the fabric, such as abrasion resistance, flex abilities, and seam strength, etc. In this way, it will help the wearers select the appropriate fabric of protective clothing for their work environment.

On the other hand, there are three safe designs of protective clothing that shall be considered to keep the liquid chemicals away from the skin or body during the working process. Firstly, the frontline operators can select protective suits with attached hood for head protection. Secondly, the safe design of the elasticated wrist and ankle can be ensured to fit the body shape, which reduces the risks of contacting the liquid chemicals from the gap between clothing and skin. Thirdly, the storm flap which covers the zipper shall also be taken into consideration since it can prevent liquid penetration from the zipper. Fourthly, for some highly toxic detergents, the seams should be sealed with adhesive tape to avoid contact with the skin. Thus, the more features of clothing design for preventing liquid; the safer the protective clothing would be.

3. Comfort and breathability

In addition to the functional points of view above, a comfortable wearing experience would be another advantage for selecting protective clothing while cleaning and disinfecting. For example, the fabric with both liquid-proof and breathability features would be a better option than a liquid-proof only fabric. The breathability will allow body heat to pass through the fabric to prevent the heatstroke illness, especially while the wearers are doing lots of exercise during disinfection.

The ergonomic design can also make a huge improvement in comfort. A head shape fitting hood can cover most of the head area and match the respirators on the face. The elasticated waist is just like a waistbelt for a one-piece suit to modify the curve around the waist and reduce the difficulty of hand movement. An ample crotch of pants allows extra space when stride or squat.

Figure 2: Operators wear appropriate protective clothing and other PPE for environmental disinfection.

(Photo credit to: Eleven Media Group)

Conclusion

Nowadays, most frontline operators wear regular clothes and masks to perform cleaning and disinfection tasks. To protect operators who use chemicals for cleaning and disinfection, ensure that they all know how to select appropriate protective clothing and keep the guidelines in mind through safety plan as well as consistently practice for cleaning and disinfection. Besides, some cleaning chemicals may cause various health and safety issues, hence please select the proven formula cleaner and also note that limited-use PPE must be removed and discarded as soon as the cleaning or disinfecting tasks are completed due to the risk of chemical exposure. Furthermore, remember that always read the spec sheet and follow the instruction of the product to ensure the protection level has covered the risk level. All in all, a healthy and pleasant frontline operator may make the environment cleaner and safer in return!