When your working environment contains hazardous liquid such as blood, chemical liquid, or acids, wearing personal protective equipment (PPE) can keep you safe and reduce the risks of contact with the hazards. However, have you ever experienced sweating all over your body after a long day at work while wearing a coverall? To keep your comfort and efficiency and prevent the risky liquid at the workplace, wearing the coverall which is made by microporous fabric will be a popular solution.

What is the microporous fabric?

Microporous fabric is made up of nonwoven laminated microporous film, which is a light fabric that offers good breathability while remaining substantially impermeable to liquid. However, do you know how to maintain both breathable and liquid-proof at the same time?

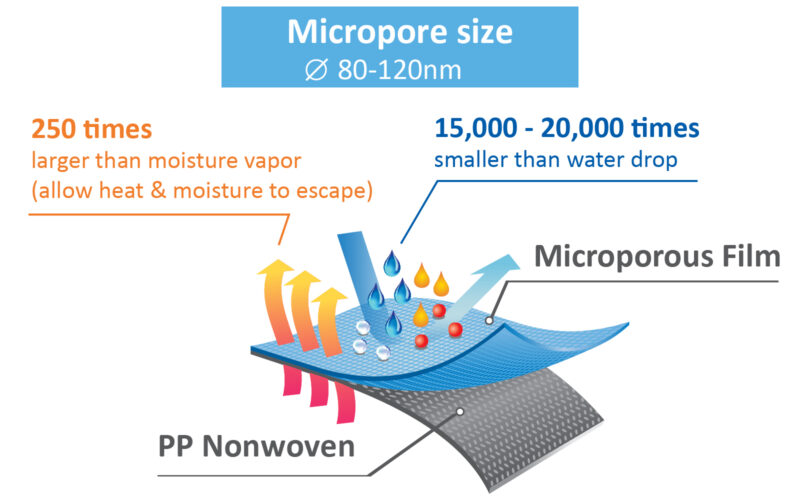

To avoid liquid and blood penetration, the size of micropores is smaller than water drops and greater than moisture vapor. Besides, the winding holes are often stacked in several layers to allow moisture vapor molecules to flow while keeping liquids out. The micropore size of microporous fabric, for example, is on average 80-120 nm in diameter, which is 250 times larger than moisture vapor and 15,000-20,000 times smaller than a drop of water, as illustrated in Figure 1. This is how it manages the features of breathability and liquid protection.

Figure 1. ULTITEC Fabric Construction

The applications of microporous fabric include disposable items for medical, industrial, and consumer products, such as protective clothing, gowns, patient suits, coveralls, boots, and so on.

Coverall fabric structures

The fabric structures of the coverall also determine the breathability and liquid-proof function, which are compared in the table below by three fabric constructions: Multi-layer Spunbonded Melt-blown Spunbonded (SMS) fabric, Microporous film laminated PP nonwoven (PPSB), and Impervious PE coated fabric (PE Coated PPSB).

| Coverall Fabrics | Microporous Film Laminate PPSB |

Multi-layer SMS | PE Coated PPSB |

| Fabric

Structure |

|

|

|

| Breathability | |||

| Liquid Protection |

Table 1. Coverall fabric structures comparison

- Microporous Film Laminate PPSB

It provides both premium breathability and liquid protection and can be used to handle hazardous liquids fluids, and the ability to allow water vapor to pass through the fabric will keep you comfortable at work.

- Multi-layer SMS

It is more breathable than the other two, but it only provides limited liquid spray protection. However, it offers superior particulate protection and is appropriate to use when working with dust, asbestos, or construction.

- PE Coated PPSB

Even though the special PE coated on PP nonwoven formula is not breathable, it provides an excellent external barrier against extremely dangerous hazards, directional liquid jets, and a wide range of chemicals. It can be used in petrochemical, oil and gas, and power plant, etc.

How to select an appropriate microporous fabric coverall?

After learning the facts about microporous fabric coveralls, you should consider 3 critical factors before choosing the appropriate one for your workplace.

1. The quality of microporous fabric

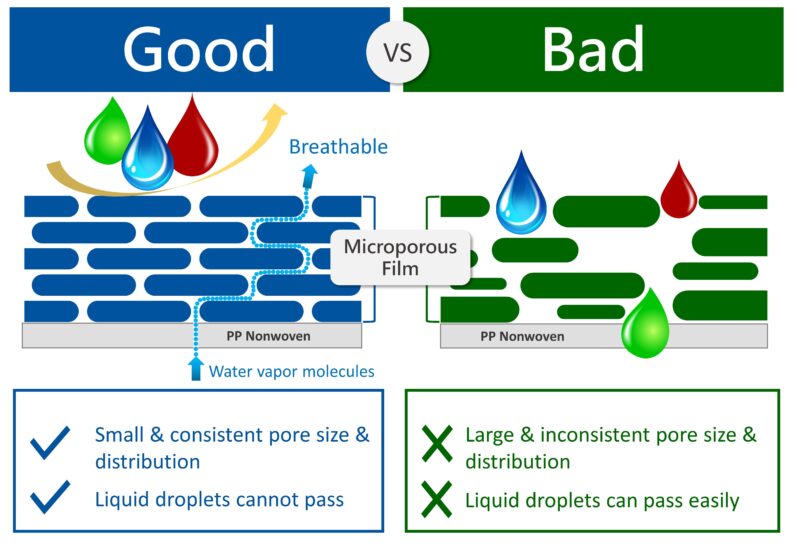

A good-quality microporous film has small micropores and consistent pore distribution to resist liquid and fluid, and the moisture vapor can easily discharge through the multi-layer winding holes. In contrast, the poor quality of microporous materials will allow risky liquids to penetrate through the microporous film due to its large pores and inconsistent pore distribution.

Figure 2. Microporous film quality comparison

2. Measurement of breathability

- You can choose breathable microporous fabric protective clothing to keep your body comfortable while working by looking at the Moisture Vapor Transmission Rate (MVTR) and Resistance to Evaporating Heat Transfer (Ret).

Moisture Vapor Transmission Rate (MVTR)

- It is a vapor barrier permeability measurement that refers to the rate at which sweat evaporates from the skin. Higher values indicate that vapor and moisture are removed more effectively, and it can be used to determine how comfortable a coverall is to wear.

Resistance to Evaporating Heat Transfer (Ret)

- It determines a material’s resistance to water vapor. In contrast to the MVTR, the lower the Ret value, the lower the resistance to moisture transfer and, as a result, the higher the breathability.

3. Identify hazards and select the equivalent protection

Aside from liquid hazards, it may contain other types of hazards in the workplace. You should assess the hazards you will encounter daily and then choose an equal level of protection in accordance with Regulation (EU) 2016/425. Please refer to CE Standard for the categories of risks and related certifications, and also read the article of Instead of Getting a Coverall, “Going Home Safely” Is What We All Desire for more information.

Figure 3. The operators were cleaning the spilled oil at the Gulf of Thailand

(Photo credit to Nicolas Axelrod)

Take the application of microporous fabric coverall for example. Approximately 50,000 liters of spilled oil, causing an oil slick to float on the sea and reach the Gulf of Thailand. Thousands of workers cleaned the contaminated beach to mitigate the damage caused by this devastation. In this scenario, a Type 4 EN 14605 spray tight suit that can protect against oil and saturated liquid splash would be a good choice because it provides the required protection against the harmful oil while also preventing any potential harm to people involved.

Conclusion

Microporous fabric is made of microporous film laminate PPSB and is designed to resist liquid while providing superior breathability. In terms of both breathability and liquid protection, microporous fabric coverall provides a better wearing experience than multi-layer SMS and PE-coated PPSB fabric coveralls. To select the appropriate microporous fabric coverall, please review the manufacturer’s technical information for comparing the quality and the breathability index such as MVTR and Ret Value. Besides, take into account the hazards at your workplace and select the equivalent protection level based on the CE standard from Regulation (EU) 2016/425. By doing so, you will be not only safe but also efficient at work.