The latest March issue of Health and Safety Middle East magazine published full page article to introduce ULTITEC high-quality products; ULTITEC 2000 and ULTITEC 4000 which are suitable for multiple hazards in the workplaces.

Read the full article

Professional protective clothing manufacturer ULTITEC knows the importance of clarifying the risks in the work environment before choosing the appropriate protective clothing.

With more visitors than ever, ULTITEC’s popularity boomed at the recent Intersec show in Dubai. The question on everyone’s lips, ‘’ what is the most suitable protective clothing for our industries and applications?’’

Before looking to CE certification and testing, buyers need to know what kind of risks are present in the environment. If there are multiple hazards in the workplace, they need the protective clothing that will satisfy these demands while keeping workers comfortable and productive.

Taking the oil and gas industry as an example, a variety of hazards may be present in the working environment including potentially explosive gasses, chemicals, crude oil, sludge, and gravel. The protective clothing, therefore, should cover multiple need to resist against hazardous dry particulates, chemical liquids, and fire.

ULTITEC 2000 passed CE certification, it effectively protects the wearer from chemical liquids, fine particles, bio-infection (blood and viruses) and is anti-static. This coverall was worn when carrying out oil-leaking cleaning in Thai bay.

If the environment involves higher risks of chemicals or necessitates handling pressured liquids, buyers should consider raising the protective level.

Choosing fully sealed protective clothing, such as ULTITEC 4000, which is ergonomically designed and certificated CE type 3 will provide effective protection for frontline staffs.

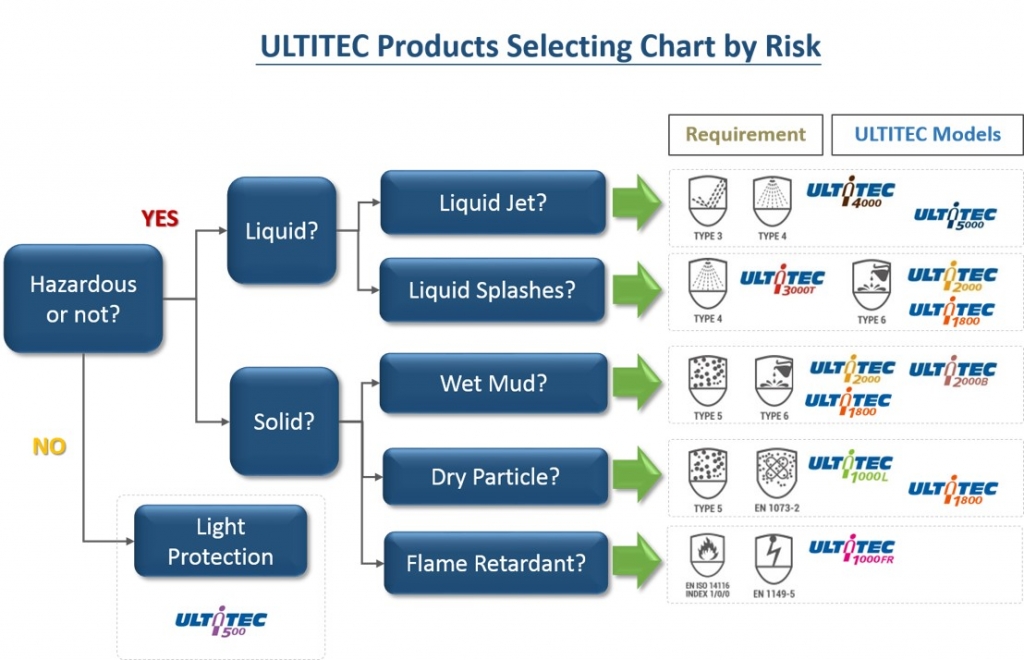

The chart below provides an easy way for consumers to understand the hazards related to the CE certification level, and the certified ULTITEC coverall’s protection levels.

ULTITEC 2000 protective clothing offers:

-

Great penetration resistance against chemical liquid, blood, body-fluid and infective agents- Passes EN368 & EN14126: performance meet WHO protective clothing standard for Ebola.

-

Low linting- Reducing the risk of contamination to work environment.

-

Suitable for cleanroom use- Pass ISO class 6 and above cleanroom standard.

ULTITEC 4000 protective clothing offers:

-

Great resistance against many chemicals, liquids, infective agents and oil- Chemical/water proof fabric & tape providing strong protection for directional liquid jet.

-

Lightweight & durability- Feeling more comfort and flexible for wearing experience.

The HSME magazine is the professional publication in the regions across Middle East and Africa for promoting occupational safety. More detail you can read the online magazine by following link: http://www.bay-publishing-magazines.com/hsme-magazine/HSMEMarch2017/