In 2020, the outbreaks of COVID-19 has forced the frontline operators to battle with the pandemic with enormous risks. ULTITEC protective clothing has made its significant presence all over the world during this battle, and we are delighted to share this article, reported on Health and Safety Middle East (HSME) Magazine in October 2020 issue with you.

In the last few months, the world has witnessed a series of outbreaks of COVID-19. Frontline operators ranged from medical personnel, police officers, chemical or biological center teams, soldiers, etc. have put their lives on the line to help the world despite great risks.

During this battle, many of them were not getting appropriate and sufficient Personal Protective Equipment (PPE). This issue became rising mental anguish, as this could potentially lead to infectious disease exposure.

ULTITEC believed these frontline operators will need appropriate protection more than anything else, no matter for now or in the future. Without them, the country is not going to work. According to a recent market research study, the protective clothing market is expected to hit USD 3.6 billion by 2024, with a CAGR of 6.5 percent from USD 2.6 billion by 2019. ULTITEC is one of the six profiled key market players that stood out as the only Asia representative in the survey.

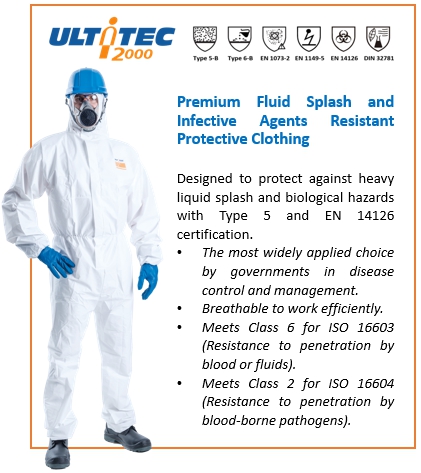

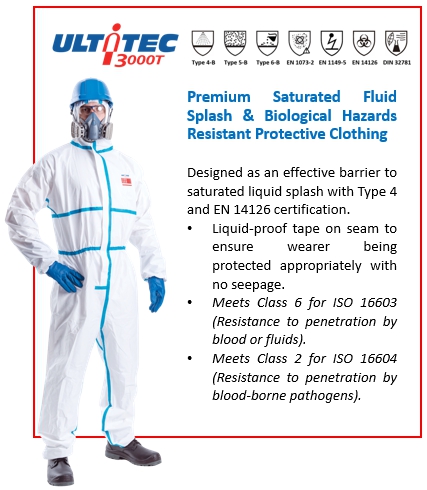

In the case of infectious disease, protective clothing with EN 14126 approved is a safer option to provide frontline operators with 360-degree body protection. This is due to potential infection risks might come from any directions, thus the protective coverage zone should cover the entire body which includes the head, arms, back and lower legs. Although gown is also one of the protective equipment, it is intended only to avoid frontal contamination, the area above and below the chest or behind the back is exposed and may cause possible infections.

To determine EN 14126, you can first identify via wording “-B” behind the “TYPE” classification, namely “TYPE 3-B”, “TYPE 4-B”, “TYPE 5-B” or “TYPE 6-B”. You might further focus on respective test methods ISO 16603 (Resistance to penetration by blood/body fluids), ISO 16604 (Resistance to penetration by blood-borne pathogens) and ISO/DIS 22611 (Resistance to liquid aerosol penetration) according to your job specification in a particular working environment.

“The Hazmat suits are part of Shell’s PPE materials for staff and the suits have an outstanding barrier against biological hazards and are suitable for H1N1 Influenza management, Ebola Virus and Covid-19 disease control”, said Philippines Shell’s Vice President for Manufacturing JP Groot-Wassink. “It is our responsibility to ensure frontline operators to ‘Act without fear!’ in their daily tasks. We want them to go home safely and resume working the next day.” said Jason Lin, Managing Director of ULTITEC.

ULTITEC protective clothing has made its significant presence all over the world. They were approved and recognized by Taiwan, Japan, Korea, Singapore, Thailand and Myanmar Governments in their disease control operations. ULTITEC partners also carried out Corporate Social Responsibility moments by protective clothing donation to frontline operators as their occupational safety shield against COVID-19. We respect and value frontline operators as national assets in any pandemic battle.

ULTITEC is abided to Regulation (EU) 2016/425 and equipped with CE certified of both Module B and Module D. Please contact us for any further information.

If you need any further assistance, please contact derekduck@derekduck.com.