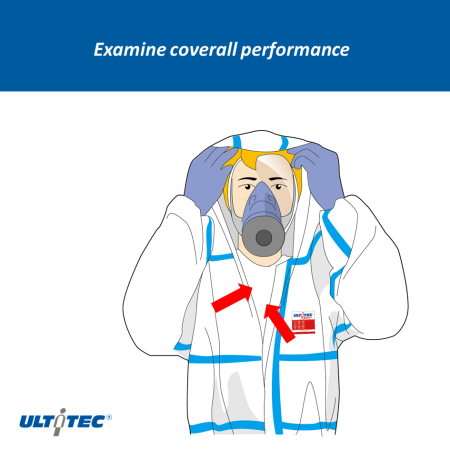

The CE certificate stands out as the most rigorous certification for coveralls. This designation is attributed to several factors. Unlike other certificates that primarily evaluate the materials and finished product of coveralls, the CE certification includes a “Real person test” to assess the garment’s ability to withstand movements during tasks. Today, we aim to provide a basic overview of the testing procedures for Type 4 (EN 14605 Liquid Jet Suits) and Type 6 (EN 13034 Reduced Spray Suits) coveralls.

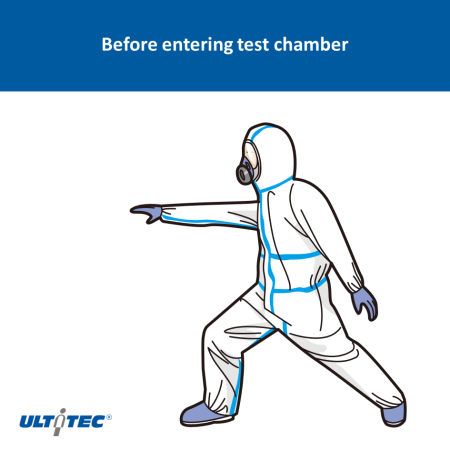

Before entering test chamber

Perform a series of movements such as climbing a ladder and crawling on the floor

This is to ensure the coverall doesn’t split or tear during your tasks.

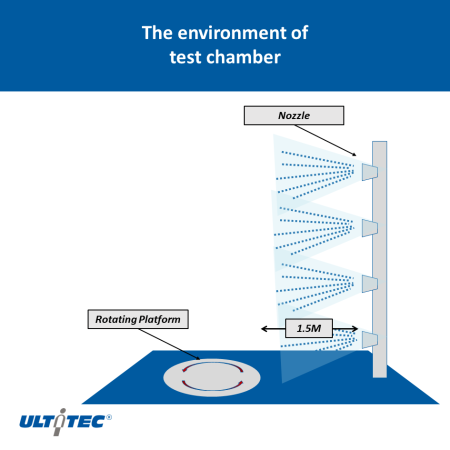

The test chamber include:

- A rotating platform, which will rotate 360° in 1 minute

- 4 nozzles with general overspray of liquid.

- There will be 1.5M between the nozzle and the subject

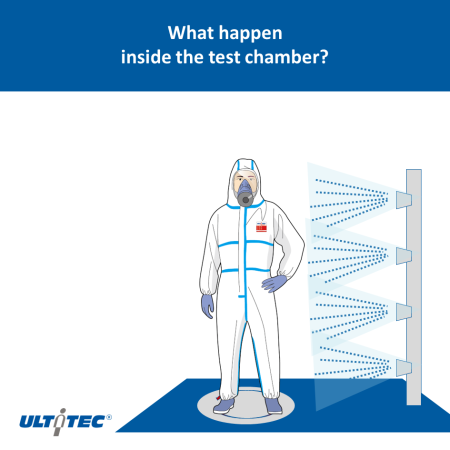

The subject will stand on the rotating platform, and perform a series of designated movement.

(EX: Knee lifts) At the same time, the suit is sprayed from all sides.

Note: “Type 4” and “Type 6” are basically the same test with different amount of water.

Finally, take off the coverall, and check the clothing beneath (See whether there is liquid spot and how much is it) to determine whether the coverall has passed the test.