Why should you pay attention for chemical safety?

As the intricacy of product designs in modern manufacturing grows, so does the use of multiple chemicals in various processes. Understanding the potential risks of these chemicals may react against the skin is crucial since many industrial chemicals can be harmful and may cause severe health problems when absorbed through the skin. When dealing with chemicals in work environment, selecting appropriate protective clothing is paramount for ensuring safety.

Selection of proper protective clothing is crucial in chemical safety. Protective clothing is designed to shield the wearer from exposure to hazardous chemicals. The question arises: How can we determine which clothing effectively prevents skin contact with harmful chemicals?

Penetration vs. Permeation

There are two important factors you may heard a lot related to chemical safety.

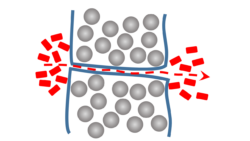

Penetration: This occurs when a chemical flows through clothing material, finding its way through openings such as zippers, weak seams, pinholes, cuts, or imperfections without changing its properties. Penetration of chemicals through protective clothing can lead to dermal exposures, making penetration testing a defect evaluation, an assessment of how a substance flows through openings.

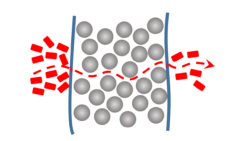

Permeation: This is the process by which liquid or gas chemicals move through material on a molecular level. It involves the sorption of molecules into the outer material surface, diffusion through the material, and subsequent desorption from the opposite side. Permeation testing evaluates how chemicals move through protective garments without passing through voids or imperfections.

Penetration

Permeation

Pic 1: Idea of penetration & permeation.

While permeation and penetration represent different mechanisms of chemical protection, it’s crucial to understand that permeation can occur and cause harm even penetration doesn’t happen. Fully comprehending the proposed permeation is essential, it’s better using permeation test result as a key element in selecting chemical protective clothing.

EU Classification for Permeation Test Result

The major permeation test standards, such as ASTM F73, IOS 6529, EN 16523-1, and EN 374, measure how fast a chemical diffuses through tact material when permeation occurs. Based on the test method, Permeation Rate (PR) and Breakthrough Time (BT) are two essential parameters in the test report, helping classify the protective level of the fabric.

Permeation rate is the speed at which a certain mass of chemical moves through the material under a specific time. It is measured in a laboratory and expressed in units like milligrams per square meter per minute. A higher permeation rate indicates a faster movement of the chemical through the material.

Breakthrough time is the time it takes for a chemical to permeate completely through the material. It is determined by applying the chemical on the glove exterior and measuring the time it takes to detect the chemical on the inside surface. Breakthrough time gives an indication of how long the material can be used before chemical permeation occurs.

The European classification system categorizes results into six classes based on normalized breakthrough time at the permeation rate of 1.0µg/cm²/mins. according to EN 14325:

- Class 6: >480 mins.

- Class 5: >240 mins.

- Class 4: >120 mins.

- Class 3: >60 mins.

- Class 2: >30 mins.

- Class 1: >10 mins.

Pic 2: Check datasheet of material of protective clothing before entering chemical exposure environment.

When working in an environment where exposure to hazardous chemicals cannot be eliminated, a chemical protective clothing is essential to minimize exposure levels below the danger threshold. The goal is to reduce exposure level considered safe for workers, even below the statutory occupational exposure limit.

The selection of appropriate chemical protective clothing involves several crucial factors. Firstly, the clothing type must be carefully chosen based on its leak tightness and garment structure. Different types of clothing offer varying levels of protection, and the appropriate selection depends on the specific hazards encountered.

Secondly, the resistance of the clothing material to permeation or penetration by chemicals must be thoroughly evaluated. The resistance of the material to chemical permeation is critical for ensuring effective protection against hazardous chemicals.

In situations where the chemical hazard is limited to specific body parts, partial body protection garments may be an appropriate option. These garments are designed to protect only the exposed areas, such as arms, chest or legs, and are marked with “PB” following the type of designation.

It is important to note that chemical protective clothing may only be suitable for limited use, especially when dealing with highly hazardous chemicals. Permeation may occur without visible penetration, making it impossible to guarantee the safety of reused garments. Therefore, single-use garments are often recommended for handling particularly dangerous chemicals.