According to the Bureau of Labor Statistics (BLS) in US in 2020, there were over 23,000 cases of occupational injuries and illnesses due to exposure to harmful substances or environments. This result includes cases where frontline operators were exposed to chemicals and lack of chemical safety in the workplace.

The chemical hazards are present in many workplaces and can cause a wide range of injuries and illnesses, including:

- Burns: Chemicals can cause chemical burns, which can be severe and require medical attention.

- Respiratory problems: Chemicals can cause respiratory problems such as asthma, lung damage, and bronchitis.

- Poisoning: Chemicals can cause acute or chronic poisoning, which can result in symptoms such as nausea, headaches, and seizures.

- Cancer: Exposure to certain chemicals, such as benzene and asbestos, can increase the risk of developing cancer.

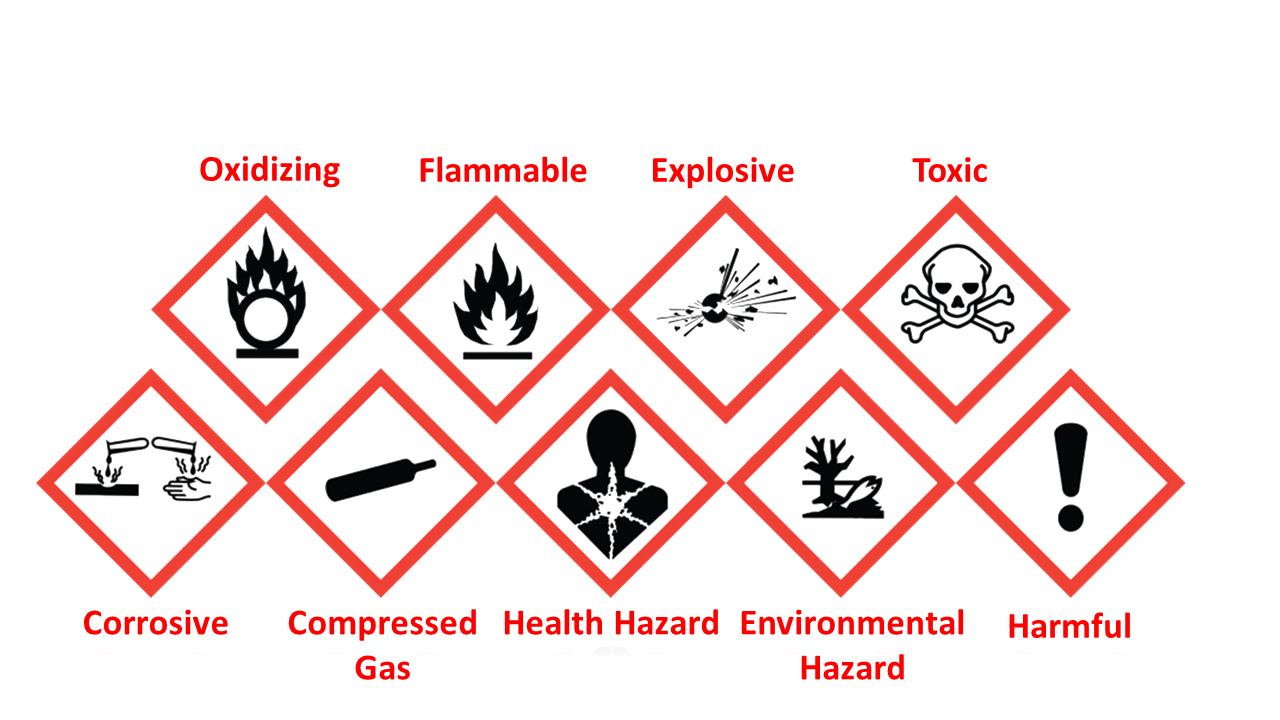

There is a symbol program from GHS (Globally Harmonized System of Classification and Labelling of Chemicals) labelling of containers and workplace hazard. These hazard pictograms help us to know the presence of a hazardous chemicals might cause harm to frontline worker and the environment.

Pic 1: Meaning of GHS Symbol for Each Hazard Pictograms

How to perform a risk assessment

Performing a risk assessment in chemical safety is very important step to ensure the safety of frontline operators in any work environment that involves the handling and use of chemicals. Here are the steps how to perform a risk assessment for a general work environment:

- Identify the chemicals: This involves creating a comprehensive inventory of all the chemicals present in the work environment. It’s essential to review the Material Safety Data Sheets (MSDS) for each chemical to ensure that you have accurate and up-to-date information about their properties and hazards.

- Assess the hazards: When associated with the chemicals, it’s important to consider both their physical and health hazards. Physical hazards can include flammability, explosiveness, and reactivity, while health hazards can include toxicity, carcinogenicity, and skin or eye irritation. It’s also essential to consider any environmental hazards associated with the chemicals, such as the potential for air or water pollution.

3. Identify potential exposure: To identify potential exposure pathways, consider the different job tasks that involve handling or using chemicals. For example, frontline operators who mix or transfer chemicals may be exposed through inhalation, skin contact, or ingestion. Frontline operators who clean up spills may be exposed through skin contact or inhalation.

4. Evaluate the risks: Once you have identified the hazards and exposure pathways, you need to evaluate the risks associated with each one. This involves considering the likelihood and severity of harm that could result from exposure to each chemical. For example, a highly toxic chemical that is frequently used in a poorly ventilated area poses a high risk of harm to frontline operators.

5. Control the risks: After evaluating the risks, you need to implement controls to reduce or eliminate them. This can involve engineering controls, such as ventilation systems or enclosed workspaces, administrative controls, such as standard operating procedures or training programs, and personal protective equipment, such as gloves or respirators.

6. Monitor and review: Regular monitoring and review of risk assessments are essential in ensuring the safety of frontline operators in a hazardous work environment. It involves conducting monitoring or other tests to measure the levels of chemicals exist in the work environment to identify any new hazards that may have arisen.

7. Training: Regular training and communication with frontline operators are also critical in keeping them informed of the risks associated with working with chemicals and the controls in place to protect them. This includes providing appropriate personal protective equipment, such as gloves and respirators, and training on their proper use. Workers should also be trained on standard operating procedures, and administrative controls such as signage and labeling should be clearly displayed to prevent accidental exposure.

In general, not doing a risk assessment can be a costly mistake that can result in harm to frontline operators, damage to the environment, and legal liabilities for the company. Overall, a comprehensive chemical safety program that includes identifying and assessing hazards, evaluating risks, implementing controls, and monitoring and reviewing the program regularly can greatly reduce the risk of harm to frontline operators in a hazardous work environment. By following these specific instructions, you had conducted a risk assessment in chemical safety for a general work environment and help to protect frontline operators’ health and safety.

The reason not performing a risk assessment

There are several reasons why frontline operators may not conduct the risk assessments:

- Lack of training: Many frontline operators may not received adequate training on how to conduct a risk assessment or may not understand its importance in ensuring their safety.

- Lack of awareness: The frontline operators may not be aware of the potential hazards associated with the chemicals they work with or the importance of assessing those risks.

- Time constraints: Frontline operators may feel that conducting a risk assessment takes too much time and interferes with their ability to complete their work tasks.

- Overconfidence: Frontline operators may have a false sense of security and believe that they are familiar with the hazards and risks associated with their work environment, leading them to skip the risk assessment process.

- Complacency: If a company has not experienced any significant accidents or incidents in the past, frontline operators may become complacent and fail to recognize the importance of conducting regular risk assessments.

Pic 3: Conduct a Risk Assessment

To encourage frontline operators to conduct risk assessments, it is important to provide them with adequate training and support, and to communicate the importance of conducting risk assessments and reporting hazards. With proper risk assessments and controls in place, frontline operators can perform their jobs safely and confidently.

How to help worker do the risk assessment before entering work

- Provide Training: The frontline operators need to be trained on how to identify hazards and assess risks before starting work. This training should include information on the types of hazards they may encounter, how to identify them, and how to assess their potential risk. Workers should also be trained on how to use any tools or resources provided to them to help them conduct a risk assessment.

- Provide Tools: The frontline operators should be provided with tools to assist them in conducting risk assessments. These tools may include checklists, guidelines, and reference materials. Checklists can help frontline operators identify hazards and assess their potential risk, while guidelines can help them understand how to manage those risks. Reference materials, such as Material Safety Data Sheets (MSDSs), can provide information on specific chemicals and their hazards.

- Involve Workers: The frontline operators should be encouraged to provide input and feedback on the risk assessment process. By involving workers in the process, they will feel more invested in the outcome and be more likely to take ownership of the risks and hazards associated with their work. This can lead to a safer work environment overall.

- Make It Routine: Risk assessments should be a routine part of work activities. The frontline operators should understand the importance of conducting a risk assessment before starting work and be aware of the consequences of not doing so. Employers should make it clear that risk assessments are a mandatory part of their work activities and that frontline operators who fail to conduct them may face disciplinary action.

- Provide Support: The frontline operators should be offered support and resources to help them conduct effective risk assessments. This may include access to safety professionals, who can provide guidance and advice on the risk assessment process. Employers should also provide frontline operators with any necessary personal protective equipment (PPE) to help mitigate the risks associated with their work. By offering frontline operators support and resources, they will be better equipped to conduct risk assessments and make informed decisions about their work.

Performing a risk assessment is crucial for ensuring the safety of workers in a hazardous work environment. Failing to do risk assessment may cause serious consequences, including injuries or illnesses caused by exposure to hazardous chemicals. The benefits include improved safety, increased awareness of potential hazards, regulatory compliance, and cost savings through injury prevention and equipment damage prevention