ULTITEC 5000

Defend Wide Range of Chemicals and Toxic Liquid Jets Resistant Protective Clothing

Designed for extremely hazardous conditions. It protects wearers from wide range of toxic chemical liquid jets.

Features

- Exceptional barrier against wide range of toxic liquid chemicals.

* Check chemical permeation data for safe usage. - Pass EN ISO 27065 and reach level C2, suitable for wearers when applying pesticides.

- Sealed seam with compatible chemical-proof tape.

- TYPE 3 EN 14605 Liquid Tight Suits- Suits which can protect against strong and directional jets of a liquid chemical such as spray from a burst pipe under pressure.

- TYPE 4 EN 14605 Spray Tight Suits- Suits which can protect against saturation of liquid chemical, where volume of the liquid builds up on the suit forming pools, resulting in rivulets.

- TYPE 5 EN ISO 13982-1 Dry Particle Suits-Suits for protection against hazardous dusts and any dry particles.

- EN 1149-5 Electrostatic dissipative protective clothing with a surface resistance of maximum 2.5×10 exp 9 ohm.

- EN 1073-2 Protective clothing against particulate radioactive contamination.

- EN 14126 Protective clothing can resist against biological hazards and infective agents.

Applications

Chemical Handling, Decontamination, Disaster Management, Petrochemical, Tank Cleaning, Oil Refinery

Color

- White/Silver

Related Information

Product Technology

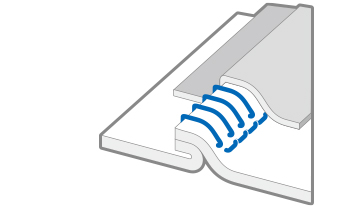

Seam Construction

4-thread Overlocked Seam with Chemical Liquid-proof Tape

- 7-9 stitches per inch

- Thread fiber is 300D

- Bite depth at 4 mm

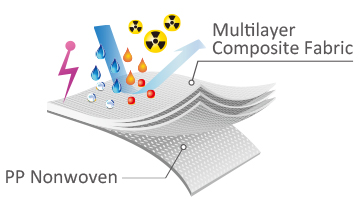

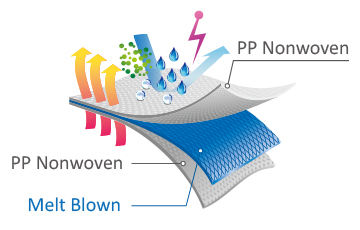

Fabric Construction

Multilayer Composite Film

Back Fabric

Multilayer SMS fabric

Performance Chart

- Scroll the form to see more.

| PHYSICAL PROPERTIES | TEST METHOD | CLASS | |

|---|---|---|---|

| Abrasion Resistance | EN 530 | 6 | |

| Flex Cracking Resistance | EN ISO 7854-B | 6 | |

| Trapezoidal Tear Resistance | EN ISO 9073-4 | 4 | |

| Tensile Strength | EN ISO 13934-1 | 3 | |

| Puncture Resistance | EN 863 | 2 | |

| Seam Strength | EN ISO 13935-2 | 4 | |

| Antistaticity | EN 1149-5 | Pass | |

| pH Value | EN ISO 3071 | Pass | |

| Resistance to Ignition | EN 13274-4 | Pass | |

| Pesticides Protective Clothing | EN ISO 27065 | Pass |

| CHEMICAL PROPERTIES | TEST METHOD | PENETRATION | REPELLENCY |

|---|---|---|---|

| Sulfuric Acid 30% | EN ISO 6530 | Class 3 | Class 3 |

| Sodium Hydroxide 10% | EN ISO 6530 | Class 3 | Class 3 |

| o-Xylene | EN ISO 6530 | Class 3 | Class 3 |

| Butan-1-ol | EN ISO 6530 | Class 3 | Class 3 |

| AGAINST INFECTIVE AGENTS with EN 14126 | TEST METHOD | CLASS | |

|---|---|---|---|

| Resistance to penetration by blood / fluids | ISO 16603 | 6 | |

| Resistance to penetration by blood-borne pathogens | ISO 16604 | 6 | |

| Resistance to wet microbial penetration | ISO 22610 | 6 | |

| Resistance to liquid aerosol penetration | ISO/DIS 22611 | 3 | |

| Resistance to dry microbial penetration | ISO 22612 | 3 |

| WHOLE SUIT TEST PERFORMANCE | RESULT | |

|---|---|---|

| Type 3 | Jet test | Pass |

| Type 4 | Spray Test | Pass |

| Type 5 | Inward Leakage Test | Pass |

| Type 6 | Reduced Spray Test | Pass |

| EN1073-2 | Against Radioactive Contamination | Class 2 |

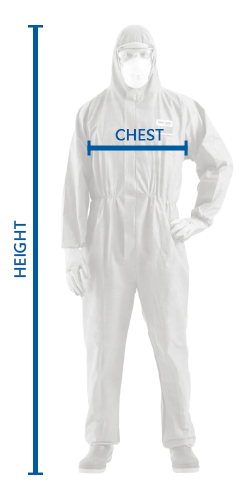

Coverall Size Chart

| SIZE | CHEST(CMS) | HEIGHT(CMS) |

|---|---|---|

| S | 84-92 | 162-170 |

| M | 92-100 | 170-176 |

| L | 100-108 | 176-182 |

| XL | 108-116 | 182-188 |

| 2XL | 116-124 | 188-194 |

| 3XL | 124-132 | 194-200 |

| 4XL | 132-140 | 200-206 |