ULTITEC 1800T

Oil & Saturated Splash Resistant Protective Clothing

Designed as a barrier to saturated liquid. It offers good protection and breathability with Type 4 certification.

Features

Proven protection of fabric performance against industrial chemicals

Act as a barrier against liquid penetration and repellency which meets EN 6530 standard..

Breathable & Comfortable

High water-vapour transmission rate results in good breathability and soft texture ensures wearer’s comfort.

Low Linting

Reduces risk of fibre contamination in workplace.

Sealed seam offers premium protection

Liquid-proof taped on seam to ensure wearer being protected with no seepage.

- TYPE 4 EN 14605 Spray Tight Suits- Suits which can protect against saturation of liquid chemical, where volume of the liquid builds up on the suit forming pools, resulting in rivulets.

- TYPE 5 EN ISO 13982-1 Dry Particle Suits-Suits for protection against hazardous dusts and any dry particles.

- TYPE 6 EN 13034 reduced spray -suits which offer limited protection against a light spray of liquid chemicals.

- EN 1149-5 Electrostatic dissipative protective clothing with a surface resistance of maximum 2.5×10 exp 9 ohm.

- EN 1073-2 Protective clothing against particulate radioactive contamination.

- EN 14126 Protective clothing can resist against biological hazards and infective agents.

Applications

Agriculture, Automotive, Biological Hazards, Chemical Plants, Disaster Management, Petrochemical, Pharmaceutical, Painting

Color

- White/Blue

Product Technology

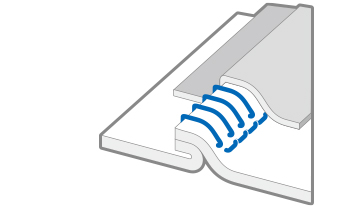

Seam Construction

4-thread Overlocked Seam with Liquid-proof Tape

- 7-9 stitches per inch

- Thread fiber is 150D

- Bite depth at 4mm

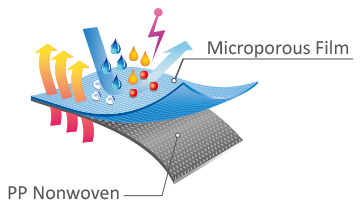

Fabric Construction

Microporous Film Laminate PPSB

- Ret value at 9.3 m²*Pa/W

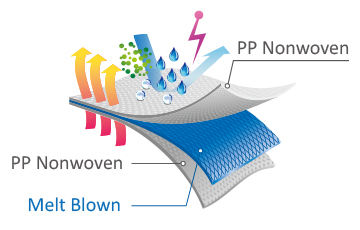

Back Fabric

Multilayer SMS fabric

Performance Chart

- Scroll the form to see more.

| FABRIC PHYSICAL PROPERTIES | TEST METHOD | CLASS | |

|---|---|---|---|

| Abrasion Resistance | EN 530 | 1 | |

| Flex Cracking Resistance | EN ISO 7854-B | 5 | |

| Trapezoidal Tear Resistance | EN ISO 9073-4 | 2 | |

| Tensile Strength | EN ISO 13934-1 | 1 | |

| Puncture Resistance | EN 863 | 1 | |

| Seam Strength | EN ISO 13935-2 | 3 | |

| Antistaticity | EN 1149-5 | Pass | |

| pH Value | EN ISO 3071 | Pass | |

| Resistance to Ignition | EN 13274-4 | Pass |

| FABRIC COMFORT PROPERTIES | TEST METHOD | RESULT | |

|---|---|---|---|

| Moisture Vapor Transmission Rate | ASTM E96 B | 7,926 g/m²*24hr | |

| Water Vapour Resistance [Ret] | EN ISO 11092 | 9.3 m²*Pa/W |

| FABRIC CHEMICAL PROPERTIES | TEST METHOD | PENETRATION | REPELLENCY |

|---|---|---|---|

| Sulfuric acid 30% | EN 6530 | Class 3 | Class 3 |

| Sodium Hydroxide 10% | EN 6530 | Class 3 | Class 2 |

| AGAINST INFECTIVE AGENTS with EN 14126 | TEST METHOD | CLASS | |

|---|---|---|---|

| Resistance to penetration by blood / fluids | ISO 16603 | 6 | |

| Resistance to penetration by blood-borne pathogens | ISO 16604 | 1 | |

| Resistance to wet microbial penetration | ISO 22610 | 6 | |

| Resistance to liquid aerosol penetration | ISO/DIS 22611 | 3 | |

| Resistance to dry microbial penetration | ISO 22612 | 3 |

| WHOLE SUIT TEST PERFORMANCE | RESULT | |

|---|---|---|

| Type 4 | Spray Test | Pass |

| Type 5 | Inward Leakage Test | Pass |

| Type 6 | Reduced Spray Test | Pass |

| EN 1073-2 | Against Radioactive Contamination | Class 3 |

Related Videos

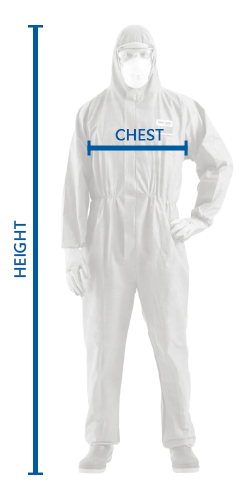

Coverall Size Chart

| SIZE | CHEST(CMS) | HEIGHT(CMS) |

|---|---|---|

| S | 84-92 | 162-170 |

| M | 92-100 | 170-176 |

| L | 100-108 | 176-182 |

| XL | 108-116 | 182-188 |

| 2XL | 116-124 | 188-194 |

| 3XL | 124-132 | 194-200 |

| 4XL | 132-140 | 200-206 |