Accidental chemical exposure in workplace can result dangers ranging from irritations to cancer and even death. According to Centers for Disease Control and Prevention, more than 13 million United States workers are potentially exposed to chemicals that can be absorbed through the skin, and countless other workers in worldwide. Thus, toxic exposure at work becoming a serious issue to be taken care of.

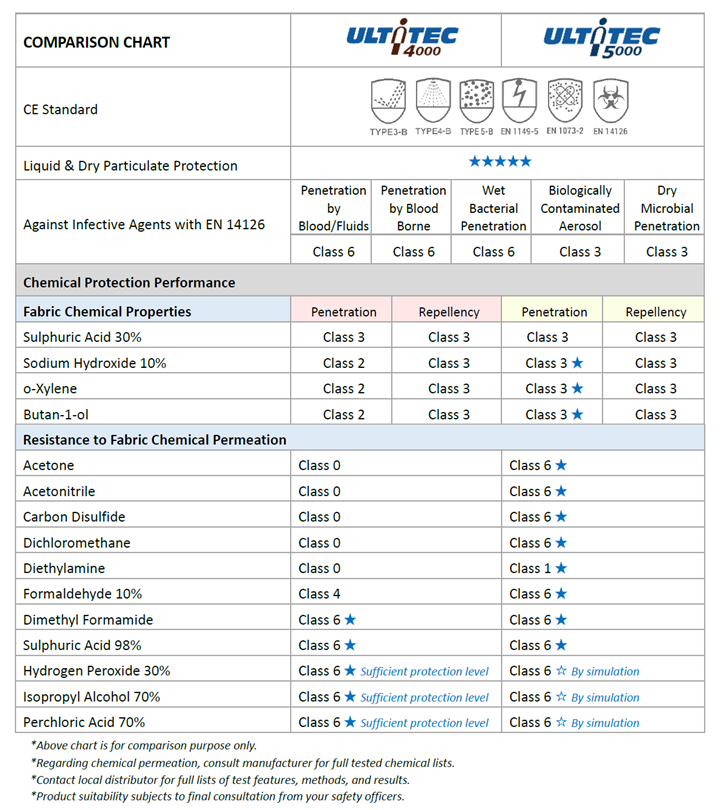

ULTITEC provides industrial protective clothing for particulate protection, flame retardant, liquid protection and chemical protection. For chemical protection, ULTITEC 4000 and ULTITEC 5000 are available for garment selection. Both are Type 3 chemical and liquid jet resistant coverall, but ULTITEC 5000 is designed for high-level purpose as made by sophisticated fabric with all seams covered by highly compatible chemical resistance tape which is suitable for extremely hazardous conditions.

ULTITEC 4000 and ULTITEC 5000 are differentiated to protect against different chemicals and chemical concentrations. ULTITEC 4000 is fully liquid-proof coverall which provides an effective shield against various chemicals, liquid jets and infective agents, with bright yellow fabric to offer high visibility. While ULTITEC 5000, as mentioned above, is super robust protective coverall mainly against wide range of both organic and inorganic toxic chemicals. They are widely applied for chemical handling, decontamination, disaster management, disease control, tank cleaning, petrochemical, oil refinery etc.

As a conclusion, consider your workplace risks before deciding on chemical protective clothing to “Act without fear!”. Variations such as different fabric physical properties, fabric chemical properties, resistance to fabric chemical permeation are the keys to determine protective capabilities. Do remember that no garment can provide absolute protection against all chemical exposures in all conditions, but higher protection level coverall is relatively more appropriate in managing uncertainty in the workplace.