When selecting protective clothing for hazardous environments, choosing the right coverall is crucial to ensure worker safety and compliance. Although ULTITEC 4000 and ULTITEC 4000S share the same high-performance fabric and appear similar, they are designed for different protection needs. Understanding their differences will help you select the right solution for your workplace.

ULTITEC 4000

ULTITEC 4000 is designed for maximum protection in high-risk environments. Certified for Type 3-B, Type 4-B, and Type 5-B, it offers strong defense against liquid jets, high volumes of liquid chemicals. It’s also certified under EN ISO 27065 C2, making it ideal for pesticide application and other tasks involving dangerous chemicals where high chemical exposure is a concern.

ULTITEC 4000S

ULTITEC 4000S, while offering Type 5-B, and Type 6-B certification, is made from the same fabric as ULTITEC 4000 and protects against the same chemicals. The key difference is that ULTITEC 4000S is better suited for tasks where workers may encounter chemical splashes rather than high-volume liquid or directional liquid jets. This makes ULTITEC 4000S an excellent choice for environments where protection from hazardous chemicals is necessary but exposure to large liquid volumes is less likely.

Design Features: Tailored for Specific Applications

While both coveralls share the same chemical-resistant fabric, their design features are customized for different scenarios:

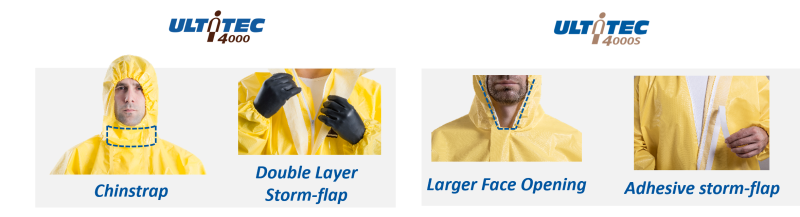

ULTITEC 4000:

- Chinstrap for a tighter seal, providing additional protection around the neck area.

- Double-layer adhesive storm flap over the front zipper, ensuring better defense against chemical penetration.

ULTITEC 4000S:

- Larger face opening to accommodate a respirator, offering a balance of protection and comfort for workers requiring respiratory equipment.

While ULTITEC 4000 and ULTITEC 4000S may appear similar and use the same fabric, their designs cater to different protection requirements. ULTITEC 4000 is your go-to solution for environments with high-volume chemical exposure or liquid jets, offering the highest level of safety for demanding tasks like pesticide application. Meanwhile, ULTITEC 4000S provides excellent chemical splash protection and respirator compatibility, making it ideal for environments where comfort and flexibility are as important as protection.

If you would like to learn more about ULTITEC 4000 and ULTITEC 4000S, please click the link below to check them out.

Choosing the Right Coverall Is Critical

Selecting the appropriate coverall is the first and most crucial step in ensuring worker safety in hazardous environments. Whether you need maximum protection for high-risk tasks like pesticide application or a more flexible solution with respirator compatibility, making the right choice can significantly reduce risks and enhance workplace safety.

To learn more about ULTITEC 4000 and ULTITEC 4000S, or to review their Chemical Permeation Data, visit the link below to check them out. Ensure your team is equipped with the best protective gear tailored to their specific needs—because safety starts with choosing the right coverall.