Why Breathability in Coveralls is Essential for Comfort and Safety

When selecting breathable coveralls for protection, the importance of breathability cannot be overstated. Beyond protection, breathable fabrics in coveralls enhance comfort by allowing moisture to evaporate, regulating body temperature, and preventing overheating.

What is Breathability in Coveralls?

Breathability refers to a fabric’s ability to allow air and moisture to pass through, a vital feature for maintaining comfort during prolonged use. In breathable coveralls, this characteristic ensures that sweat evaporates, leaving the skin dry and cool, especially crucial in high-intensity work environments.

Benefits of Breathable Fabrics in Workwear

- Enhanced Comfort: Breathable fabrics dissipate body heat through moisture evaporation, convection, conduction, and radiation, preventing heat stress and increasing tolerance during physical activities.

- Extended Wear Time: Comfortable coveralls encourage workers to wear them longer, ensuring continuous protection in hazardous environments.

Measuring Breathability: MVTR and Ret

Breathability is quantified using two metrics:

- Moisture Vapor Transmission Rate (MVTR): This measures moisture vapor passing through a fabric. A higher MVTR indicates better breathability.

- Resistance of Evaporation of a Textile (Ret): Ret measures a fabric’s resistance to moisture evaporation. Lower Ret values mean better breathability.

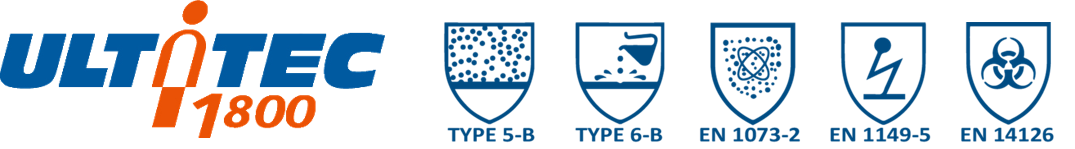

Oil & Liquid Splash Resistant Protective Clothing

- Widely applied in multiple industries with its liquid splash protection capabilities.

- Enhance your wearing experience with highly breathable fabric. (Ret value: 9.3 m²*Pa/W)