Have you ever wondered what FR coveralls stand for? Although both flame-resistant and flame-retardant coveralls are abbreviated as FR coveralls, they offer varying levels of protection. Flame-resistant garment functions normally at high temperatures but may not function normally in the event of a fire. In high temperatures or fire conditions, the flame-retardant garment will not function normally, but will actively prevent the heat source from spreading.

After understanding the functions of flame-resistant and retardant, we will further look into their levels of protection, which are classified as Primary and Secondary. The difference between these levels is the intended use of the FR coveralls and the workplace hazards that the wearers will face. The two levels of protection are briefly described below.

- Primary FR Protection (Flame-Resistant)

Primary FR protection refers to flame-resistant coveralls designed to be worn during activities in which the wearer is constantly exposed to hazards such as flames, radiant heat, arc flash or flash fire. Its purpose is to minimize burn harm by preventing or slowing the transmission of heat energy from the source to the wearer’s skin.

- Secondary FR Protection (Flame-Retardant)

Secondary FR protection is intended for the wearer who may be short-term exposed to intermittent hazards and already has Primary FR protection underneath. It provides little or no heat source protection because it is worn to protect against additional risks, such as chemicals or particulates, while also having the critical flame-retardant quality to prevent it from igniting and burning.

How Flame-Retardant Coveralls Work to Protect Wearers?

Many fabrics will ignite and continue to burn if exposed to heat source, some will also melt onto the wearer’s body. This can result in significant injuries because textile fires often burn longer and cause more damage than the initial incident. Flame-retardant coveralls are specially designed to self-extinguish, reducing the likelihood of it catching fire when exposed to combustion and high temperatures. This gives the wearer valuable escape time and helps to reduce injuries.

There are also situations where both chemical and FR protection are required, a common solution is to wear a standard disposable chemical coverall over the FR coverall. However, this creates harm to wearers because standard chemical coveralls are made of plastic-like materials, thus in contact with flames, they will ignite, burn, and drip molten debris onto the FR garments beneath, transferring additional heat energy to the skin of the wearer below. As a result, flame-retardant coveralls which provide both chemical and FR protection are applied to solve the situation. They are specifically intended to be worn on top of flame-resistant coveralls to give chemical protection without compromising heat source protection.

EN ISO 14116:2015 Limited Flame Spread Protection

EN ISO 14116 can be used to determine whether a garment does not ignite, burn or drip molten when exposed to a flame. Most flame-retardant coveralls meet the requirements of Index 1, which allows for holing but requires no blazing or melting debris, and that the flame does not burn to the sample’s edge. It essentially confirms that the fabric will not catch fire and burn.

EN ISO 14116:2015 Limited Flame Spread Protection

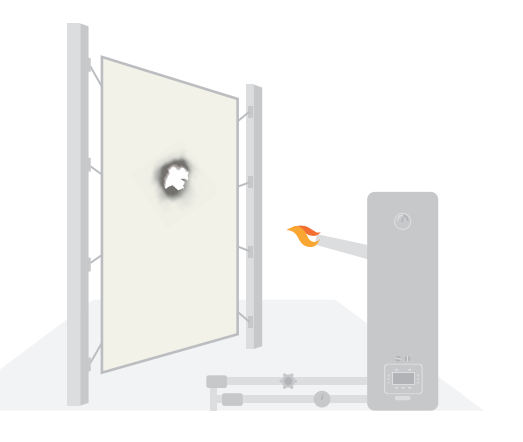

Clip the fabric vertically so that the flame burns in the middle and the outcomes of the sample fabric can be seen. It is divided into three indexes based on the state of the fire and the spread of the flame.

Pic 1: Test Method of EN ISO 14116

| Index 1 | The flame does not spread, there is no flaming debris, no afterglow, and a hole may be formed. |

| Index 2 | The flame does not spread, there is no flaming debris, no afterglow, and no hole formation. |

| Index 3 | The flame does not spread, there is no flaming debris, no afterglow, no hole formation, and the after-flame time of each specimen is less than 2 seconds. |

Chart 1: Indexes of EN ISO 14116

The Benefits of Wearing Flame-Retardant Coveralls

Hence, if you are working in a condition where additional risks and FR protection are needed at the same time, wearing flame-retardant coveralls on top of flame-resistant coveralls has several advantages:

- The flame-resistant coverall is more expensive and reusable. Wearers who wear flame-retardant coverall on top might extend the life of the flame-resistant garment.

- The cost of laundering is not cheap. To save money on laundry, using a flame-retardant coverall outside is a smart alternative for daily protective application.

- When working in chemicals or particulates environment, flame-retardant coveralls of Type 5 and 6 certifications can protect you from these hazards.

- The flame-retardant coverall is usually anti-static for flame-retardant purpose, which reduces the risk of electrostatic sparking in flammable gas environments.

Conclusion

First and foremost, determine whether your workplace requires Primary or Secondary FR protection. A risk assessment completed on-site by qualified safety managers can help with this. If there are scenarios when both additional risks (chemicals or particles) and FR protection are required, make sure the flame-retardant coveralls you choose pass the EN ISO 14116 test. Remember that flame-retardant coveralls must be worn over flame-resistant coveralls; a flame-retardant garment should never come into direct contact with the skin to avoid any possible occupational injuries

| DEREKDUCK launched own protective clothing brand ULTITEC in 2008 with brand slogan “Act without fear!”. This is to commend frontline heroes as they are the ones dealing with toxic dust or liquid hazards, and ULTITEC can be their occupational safety shield in preventing workplace disasters.

www.ultitec-protection.com |