In previous chapters, we discussed What Should You Understand About CE Test Standard for Protective Clothing, it stated clearly the standard definition of coverall and test methods for standard categorization. After we have grasped these standards, it is time to delve deeper into the fabric physical properties of the coverall, as these specific features will combine to form a qualified coverall that provides the best whole suit performance.

Fabric Physical Properties of Coverall

For coverall, it is more related to utility and durability as their production characteristics. Utility characteristics are changes in the wearing functions of a garment that occur when the fabric is subjected to a mechanical, thermal, electrical, or chemical force while being worn. While durability refers to the ability to maintain protection capabilities and wearing experiences until the maximum tolerance level is reached. It is the amount of stress that causes the fabric to break down or lose its ability to repeat a desired action or function.

Examples of Utility and Durability characteristics:

- Antistaticity

- Abrasion Resistance

- Flex Cracking Resistance

- Trapezoidal Tear Resistance

- Puncture Resistance

- Tensile Strength

- Seam Strength

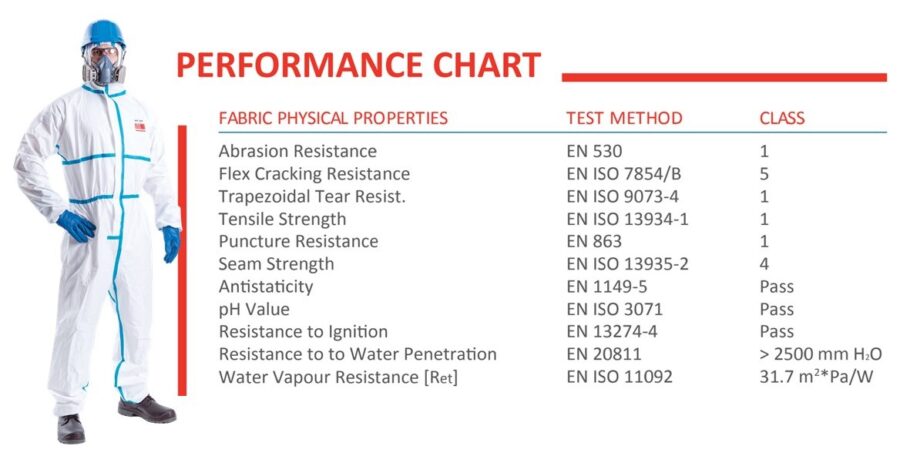

Above we mentioned only examples of both utility and durability characteristics, you may find more details in the Performance Chart or Technical Data Sheets provided by the coverall manufacturer.

Test Methods for Fabric Physical Properties

We hereby introduce some fabric physical properties and their respective test methods used. By taking a peep at these test methods, you can understand how strict for a coverall to be CE qualified. CE certification assures users that the coverall has been independently assessed and the manufacturing process is maintained to comply with those standards.

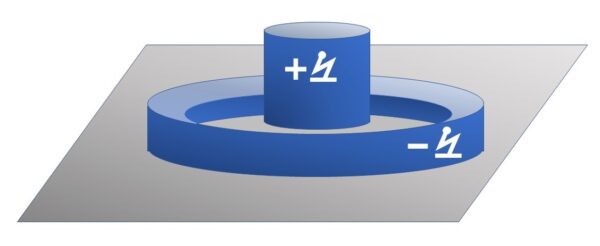

Antistaticity

Test Method – EN1149-1

To determine the resistance value of the fabric surface.

This specifies the electrostatic property requirements for safety garments to avoid incendiary discharge, which is especially important in areas where explosive atmospheres are risky.

Picture 1. Test Method for Antistaticity

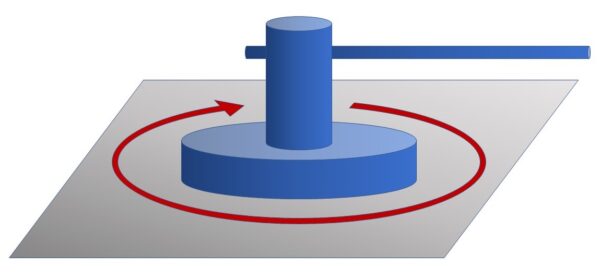

Abrasion Resistance

Test Method – EN 530 (Method 2)

To determine abrasion or rubbing resistance of fabric.

This is a critical test performed to ensure that the garment is free of defects, has a long design life, and consistently performs well. The abrasive resistance ensures that it has the necessary strength to withstand the predominant friction forces that will be subjected to.

Picture 2. Test Method for Abrasion Resistance

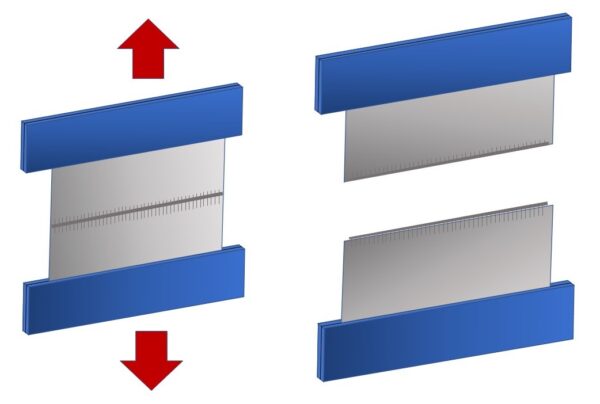

Flex Cracking Resistance

Test Method – EN ISO 7854 (Method B)

To determine the fabric resistance to the formation and growth of cracks or damages by repeated flexing.

Clamp the fabric in grip and flex it constantly, then observe the cracking degree to realize or compare its flex-endurance after flexibility fatigued. It is a measure of garment toughness, specifically its resistance when subjected to flexing abuse.

Picture 3. Test Method for Flex Cracking Resistance

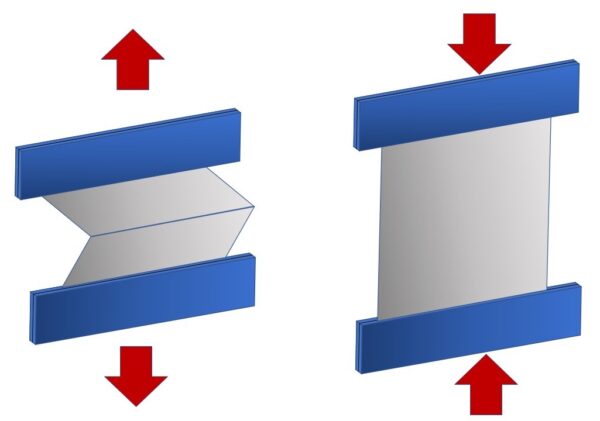

Trapezoidal Tear Resistance

Test Method – EN ISO 9073-4

To determine fabric resistance to tearing once damaged.

A force is applied to steadily extend a cut in the test fabric. This method is a tension test in which the strength is determined primarily by the fibers of the composite structure and their bonding or interlocking. It is useful for estimating the relative ease of tearing of nonwovens.

Picture 4. Test Method for Trapezoidal Tear Resistance

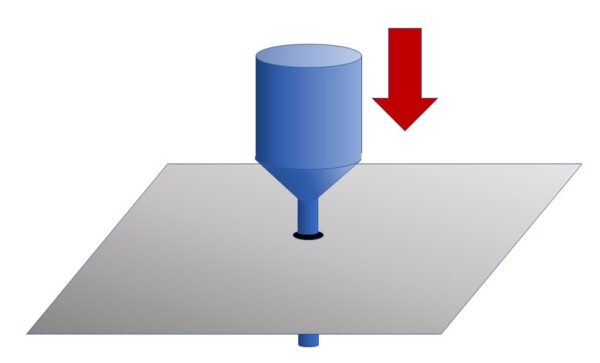

Puncture Resistance

Test Method – EN 863

To determine fabric resistance to being punctured by a force.

Puncture resistance denotes the relative ability of fabric material to inhibit the intrusion of a foreign object. The maximum force required to push the spike through the fabric is recorded as puncture resistance.

Picture 5. Test Method for Puncture Resistance

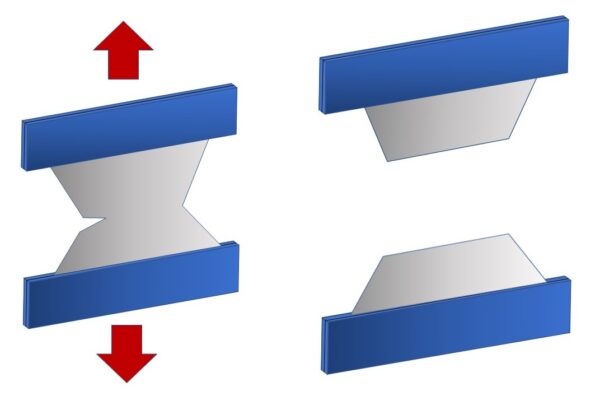

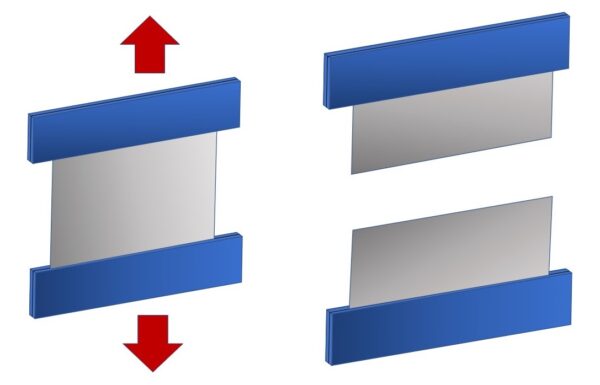

Tensile Strength

Test Method – EN ISO 13934-1

To determine the maximum load that fabric can support without fracturing when being stretched.

It is a procedure that uses a strip method to determine the maximum force and elongation at the maximum force of textile fabrics in equilibrium. Set the movable clamp in motion and extend the test fabric until it reaches the point of rupture.

Picture 6. Test Method for Tensile Strength

Seam Strength

Test Method – EN ISO 13935-2

To determine the strength of seam assembly in a garment.

This method specifies for the determination of seam maximum force of sewn seams when the force is applied perpendicularly to the seam.

Picture 7. Test Method for Seam Strength

These test results will then be evaluated and accepted by the Notified Bodies, which are authorized to issue a CE certificate for the qualified coveralls. The results of each test are based on a classification system described in EN 14325:2018, which includes all classification tables for fabric physical properties.

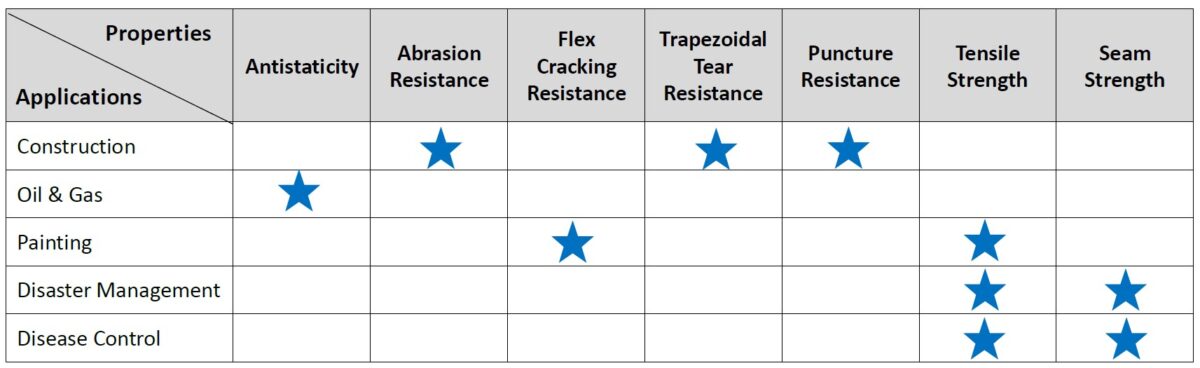

Fabric Physical Properties Can Enhance Your Job Efficiency

Users shall consider different fabric physical properties based on their job requirements in each application. Hereby listed few examples for reference.

Chart 1. Considerations of Fabric Physical Properties

For users in construction, due to working environments, durability is the main concern, thus abrasion, trapezoidal tear or puncture resistance shall be considered. While for painting, do check on the flex cracking resistance and tensile strength, as you will need a lot of major movements thus any ruptures on the coverall may delay your working schedule. While in the oil and gas industry, users shall take note of the antistaticity as static electricity can create a tiny spark which in a flammable environment is sufficient to cause major explosions. Also, for those who carry out disaster management and disease control, considerations on tensile strength and seam strength are needed, as the conditions of the on-site environment will be full of unknowns.

Conclusion

There are always other aspects to consider when selecting an appropriate coverall in addition to these fabric physical properties. The final choice must be comprehensively evaluated instead of depending on a few values. For example, the coverall must also meet certain requirements such as chemical permeation resistance, ergonomic designs, etc. There are always many perspectives from which you can examine the appropriate coverall you should wear.

In the coverall world, there is a lot of knowledge to comprehend and these hidden features will lead you to select a more appropriate coverall for your daily jobs according to your needed protection levels. By paying attention to these details on Performance Chart or Technical Data Sheets, you will discover that there is no perfect coverall, but an appropriate one is the best companion to safeguard you while completing your jobs perfectly!

Chart 2. Performance Chart of ULTITEC