Frontline workers typically refuse to wear protective clothing because it is stuffy, causes sweating, and is uncomfortable. However, the development of fabrics that combine liquid resistance with breathability became critical for a coverall. Breathable fabric can withstand liquid hazards while allowing sweat to pass through. It provides both safety and a comfortable wearing experience at the same time.

Let us learn what breathability is, how it is measured, and how useful these measurements are for our lives in working environment.

How can we measure breathability?

A fabric’s breathability refers to its ability to take away water vapors produced by perspiration. To determine breathability, the moisture vapor permeability of the breathable fabric must be tested. Many manufacturers are doing this. They do not, however, use the same test method.

Many manufacturers have used Moisture Vapor Transmission (MVT) and Thermal Evaporative Resistance (Ret) measurements to determine breathability. The Upright Cup test and the Inverted Cup test are the two methods for measuring moisture permeability. The Sweating Hot Plate test, also known as the Hohenstein Skin Model test, is used to determine the thermal resistance level of the fabric itself.

Moisture Vapor Transmission (MVT)

- Upright Cup Test

In the Upright Cup test, the cup is placed upright in a humidity-controlled environment. After a period of time, a piece of fabric is placed and secured over the cup, and the weight change is measured. The outcome is determined by how much moisture passes through, and the amount is extrapolated to grams for one square meter of fabric over a 24-hour period.

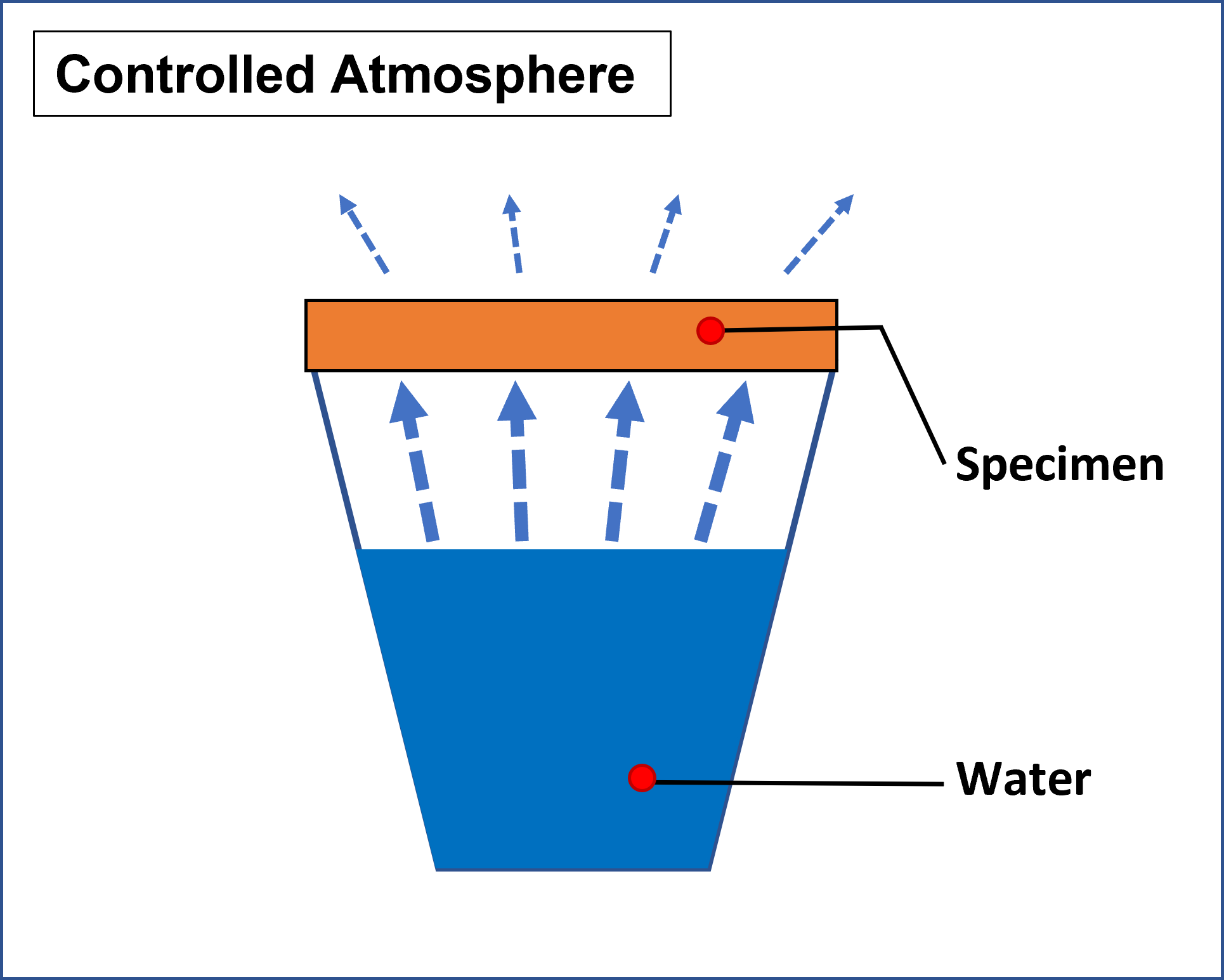

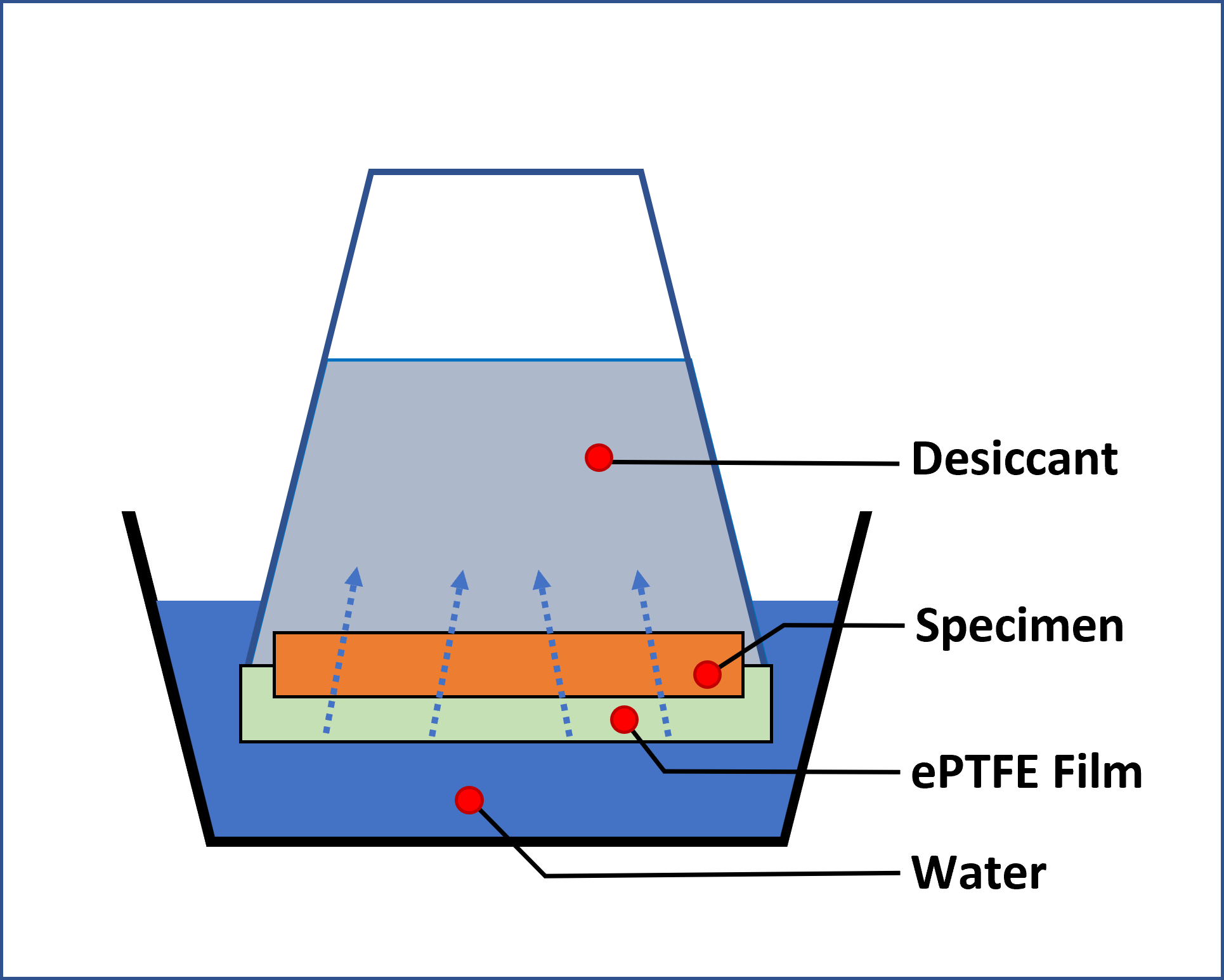

There are two types of Upright Cup test methods: the Water Method and Desiccant Method. Both Water Method and Desiccant Method are considered basic testing methods based on a straightforward principle. The Water Method uses distilled water in the cup, and the vapor moves through the specimen from the water to the controlled atmosphere. While for the Dessicant Method, the test specimen is sealed to the open mouth of a test cup containing a desiccant and placed in a controlled atmosphere. Water vapor moves from the atmosphere through the specimen and into the desiccant.

Pic 1: Water Method and Desiccant Method of Upright Cup test

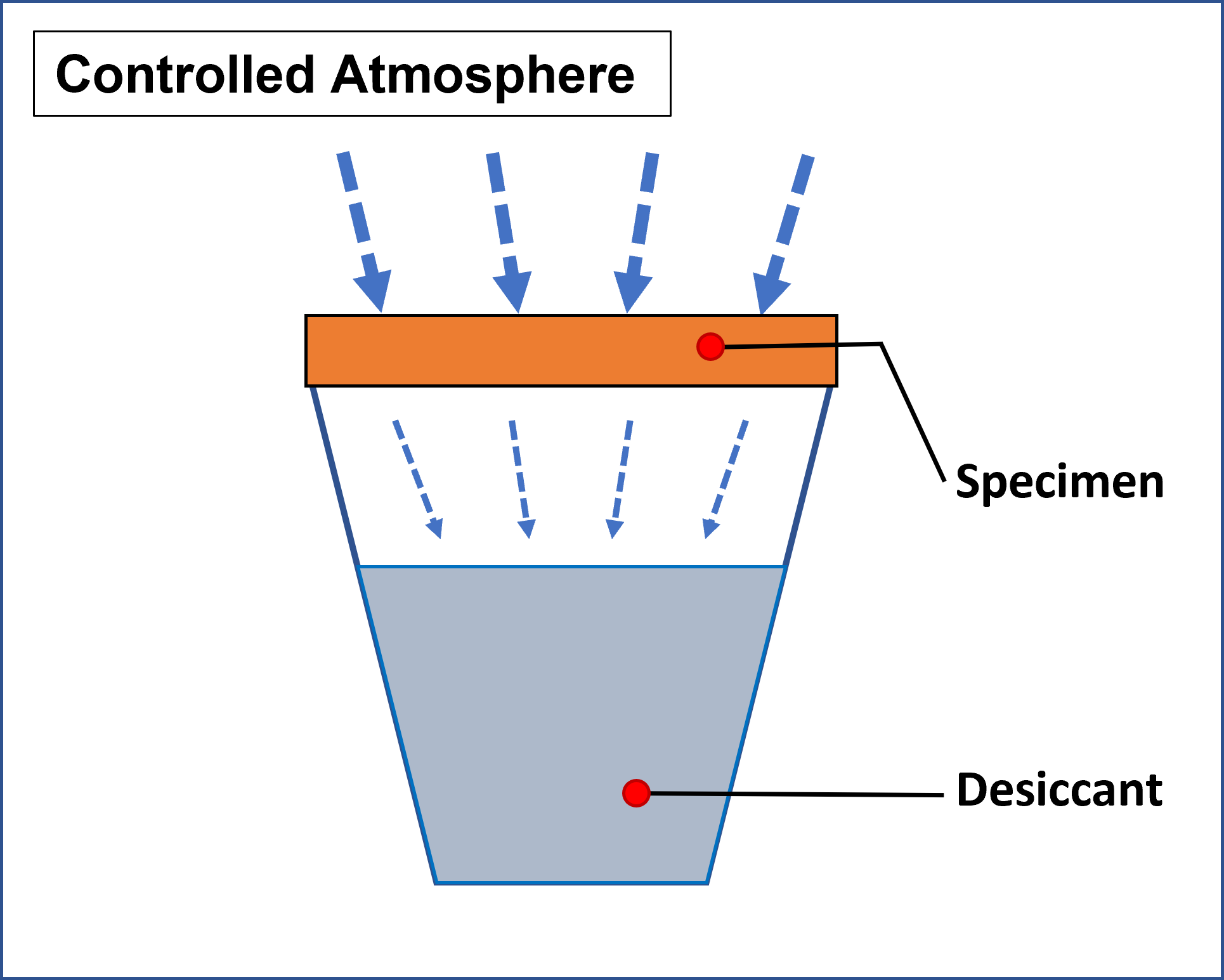

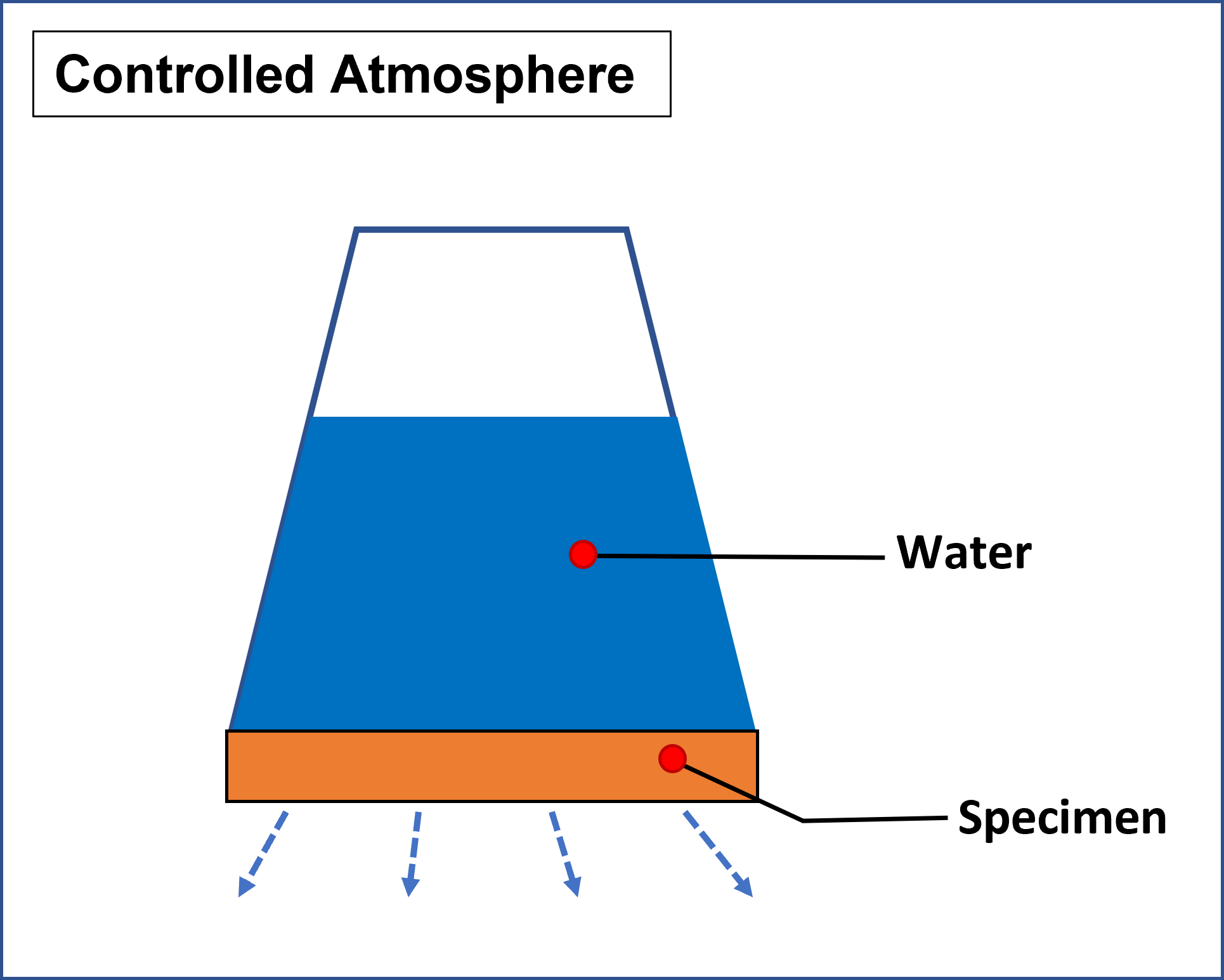

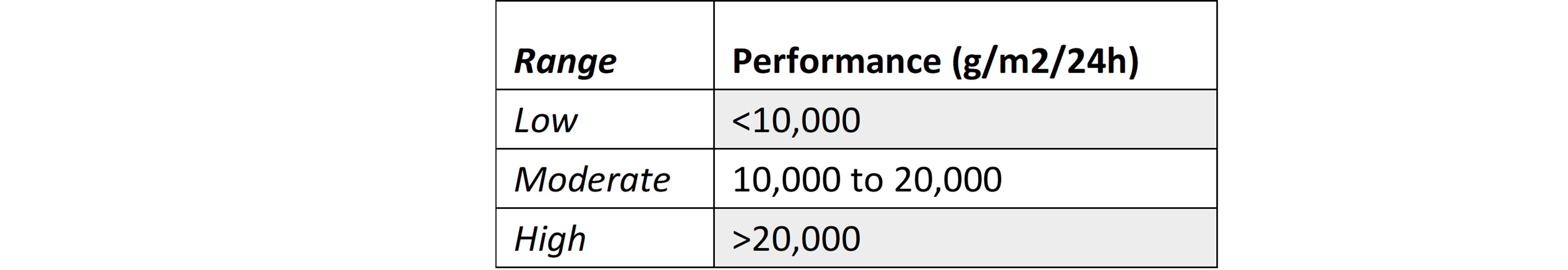

The upright cup test has many test standards, including JIS L 1099, JIS Z 0208, ISO 2528, ASTM E96, and JIS K 6328. A higher number indicates a higher transmit rate. It is roughly divided into three categories:

Table 1: Range and performance of Upright Cup test

- Inverted Cup Test

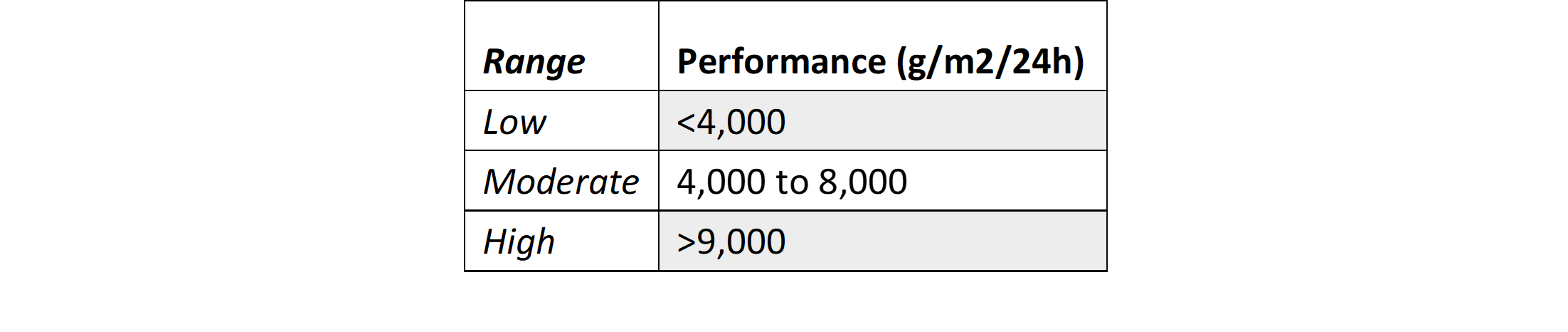

The Inverted Cup test is also known as JIS L 1099 and ASTM E96-BW. The Inverted Cup test involves placing the test specimen over a cup and then inverting it for testing. The Inverted Cup test also has two test methods. One is filling a cup with water and then inverting it to measure the weight change of water over time. The specimen comes into direct contact with water.

The other method is the desiccant method, in which potassium acetate is placed in the cup and an ePTFE film is placed over the specimen before inverting the test cup into a water dish. The potassium acetate pulls the water vapor through the fabric, and the amount of water is determined by weighing the cup after the test. The weight is then extrapolated to determine how many grams of fluid pass through a square meter of fabric in 24 hours.

Pic 2: Water Method and Desiccant Method of Inverted Cup test

The desiccant method is an excellent test for non-waterproof fabrics because it eliminates the effect of the fabric when it comes into direct contact with water. When sweat condenses on the inside of a fabric that has a hydrophilic layer, the water is actively drawn through the fabric, reducing condensation.

Table 2: Range and performance of Inverted Cup test

Thermal Evaporative Resistance (Ret)

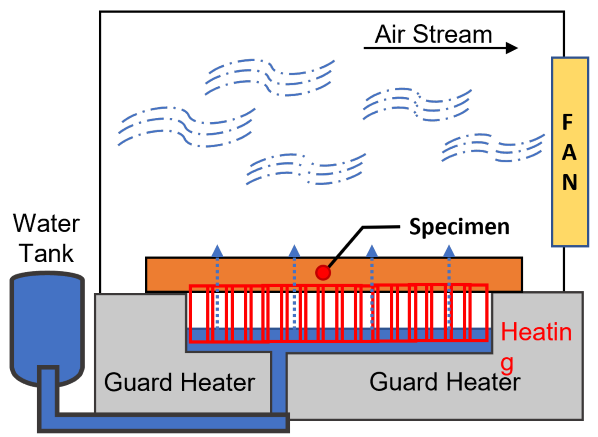

- Sweating Hot Plate Test

The ISO 11092 test method is also known as the Thermal Evaporative Resistance (Ret) or Hohenstein test. The fabric is placed above a hot porous metal plate in this test. This plate maintains a constant temperature. Water is fed from beneath to the hot porous plate, where it converts from liquid to vapor in order to pass through the plate and the fabric. Meanwhile, the evaporating water vapor causes Evaporative Heat Loss, which cools the plate. As a result, additional energy is required to keep the plate at a constant temperature.

Because the plate requires continuous heating, the demand energies can be measured and calculated. This is referred to as the water vapor resistance in physics and is expressed in the Ret value. The lower the Ret number, the greater the fabric’s breathability.

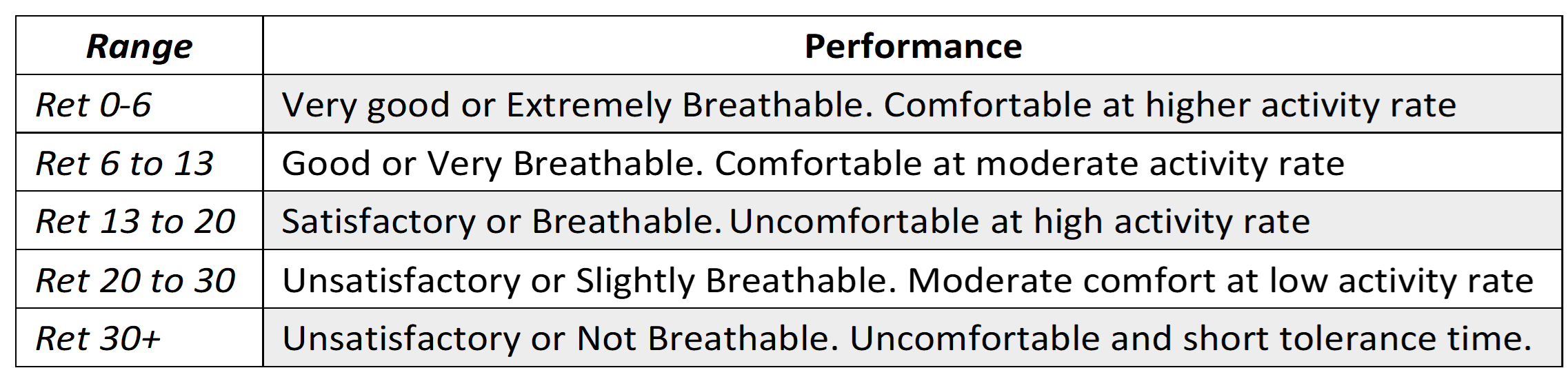

The testers couldn’t tell the difference between garments made with fabrics in these ranges. As a result, there was no discernible comfort difference in use between a garment made of fabric with a 40 Ret factor and one made of fabric with a 55 Ret factor.

Table 3: Range and performance of Sweating Hot Plate test

When liquid resistance and breathability work together

When wearing a coverall, the human body continues to heat the environment between the fabric and the skin, and sweating adds to the moisture. Both factors contribute to the microenvironment becoming too hot and humid to sustain. A higher breathability fabric moves moisture outward, keeping skin dry on the inside. Meanwhile, liquid resistance is critical to keep liquid from soaking through to your body from outside of clothing. Fabric with a higher breathability can provide more comfort.

While liquid resistance and breathability appear to be diametrically opposed, we require both functions to be active at the same time to make the coverall safer and more comfortable. There is no coverall that is completely liquid resistant and completely breathable; it is always somewhere in the middle. A good coverall strikes a balance between protection and comfort. It is pointless to have breathability if the coverall cannot protect from the working environment. It’s a mutually beneficial relationship. Because neither can function without the other, they are equally important.